For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

154/273

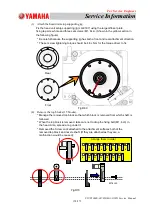

4.11.2. Nozzle Shaft Total Disassembling, Cleaning and Assembling

4.11.2.1. Purpose

The purpose of this operation is to prevent or improve on Up/Down movement error or

pick-up error due to dirt on the nozzle shaft section in the head unit in the routine automatic

operation.

4.11.2.2. Required Items for the Work

(1) Tools and Jigs

Hexagon Wrench Straight Type (TONE or BONDUS is recommendable).

Torque Driver (including bit for M1. 6L2 hexagon bolt) where 7.5 cNm can be set.

Head Unit Setup Supporting Tool (Nozzle Shaft Jump-Out Holding Bottom Cover)

Nozzle Holder Attachment/Detachment Supporting Tool

General Phillips Type Screwdriver

Linear Measure Sensor Protection Tube (or Protection Wrap)

Reference Tool: Bamboo Skewer (Used for greasing up the retainer section)

Ultrasonic Cleaner (For cleaning the nozzle shaft)

Nozzle Shaft Cleaning Supporting Tool

Lubricating Tool: SS-10LZ (Standard Accessory) and Lubrication Nozzle: Type No.

19

(2) Others

Grease (Daphne Eponex No. 1)

Screw Lock (

1401B

): Applied slightly to the fixed screws on the top block, etc.

Top Block

Set

Screw: Prepared the required number of set screws for replacement (M1.

6L3)

Diffuser

Plate

(Large, Small), Linear Measure Sensor, Lower Rotor Set Screw:

Prepared the

required

number of set screws for replacement (M1. 6L4)

V-Packing: Used in the Nozzle Holder Unit and Nozzle Shaft Outer Casing Section (15 pcs

each)

Cleaning Rag and Rags for spreading on the working floor

Nozzle Shaft Cleaning Water