For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

91/273

3.1.5. Various Settings

3.1.5.1. High-Speed Nozzle Stocker

(

1)

Various Sensor Adjustments

a.

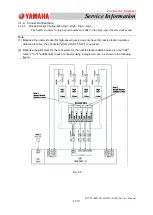

Nozzle Stocker Unit Lower Limit Sensor Check: Confirm that the light is

intercepted at the lower limit and the light is received in moving up operation.

b.

Nozzle Stocker Clamp Check: Insert the 0.3mm thickness gauge into the arrow

section (as shown in C12-(3)), and check the light receiving condition with the

nozzle stoker risen.

c.

Shutter Open/Close Sensor Check: Attach the stocker change unit and adjust it so

that the shutter is detected (light is turned OFF) at the position where the shutter is

moved 2.0 +/- 1mm in the opening direction from the shutter completely closed

position.

(2)

Nozzle Stocker Open Stroke Adjustment

Fix the cylinder stroke adjusting nut at the

position where the shutter is returned 0.15 to

0.25mm from the full open position. (Fig. C13:

yellow arrow section right figure).

*Apply Screw Lock 1401B.

(3)

Shutter Open/Close Speed Adjustment

Open the needle of the Speed Controller

(SPICON) 225 degrees (standard) from the

completely closed position.

Make sure that the shutter close time period is within the

following range in the window of the machine.

Note:

a. The shutter close time period varies depending on the No. of mounted cylinders.

b. Check the stocker change section with cylinders mounted one by one.

Needle Opening Angle

225 degrees (Standard)

No. of Cylinders mounted in the

Stocker Cylinder Section

1 Unit

2 Unit

3Unit

4 Unit

Stocker Change Section

Only one stocker mounted

MIN

160ms

200ms

200ms

250ms

MAX

230ms

350ms

390ms

400ms

Fig.C12

(1) Stocker Set

(2) No Stocker

(3) Stocker 0.3mm Risen

Fig.C13