For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

147/273

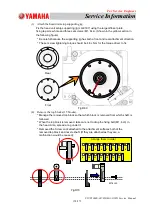

(10)

Check the height from the Placement Height Confirmation Supporting Jig (JG-0191)

to the master nozzle tip and loosen the coupling fixing bolt on the HL-axis ball screw

side to re-adjust.

For the height check, use the Placement/Pick-up Height Confirmation Jig (JG-0194)

to facilitate the operation.

Fig.D52

(11)

Select

"

Maint.

"

,

"

DVC Check

"

and

"

Motor

"

in this order and perform zeroing

operation for

"

NL

"

,

"

HL

"

,

"

NS

"

and

"

DD

"

in this order manually in the

"

Motor

"

window.

* At that time, bring the coupling fixing bolt on the HL-axis to the position where it

can be loosened easily. In the case that the bolt is not in a position where it can be

loosened easily, loosen the coupling on the motor side and adjust the position.

Then, repeat Step (10).

(12)

Perform the head up/down offset adjustment (work in the center of the machine).

Find the difference between the values recorded before the replacement and the

actual measured value.

If the difference in offset value before and after replacement is /- 0.01 mm, go

to the next item.

The difference in offset value before and after replacement, is /- 0.05 mm,

perform also the placement height offset adjustment.

* Refer to

"

1-4 Offset in the Installation Operation

"

in Chapter 1, for the pick-up

height offset adjustment.

(13)

Tighten the fixing bolts securely on the upper and lower sections of the coupling.

Tightening Torque: 47.04 cN

m

*

Apply Screw Lock (1401B) on the fixing bolts.

M2.5 should be used for the set bolts.

Height : 32mm

0.05 mm

Master Nozzle

Placement Height

Confirmation Supporting Jig JG-0191