SIPART DR20

Project Planning Manual

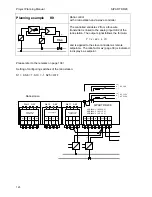

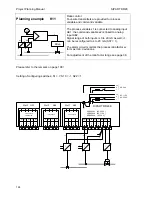

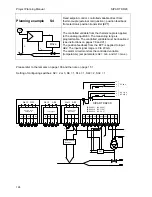

Planning example

S5

Fixed setpoint control with disturbance variable feed-

forward (two-component control). Controlled variable x1

direct from Pt 100, disturbance variable x2 from

transmitter. Position feedback from resistance transmitter

W

X

1

y

Drive

X

2

Y

R

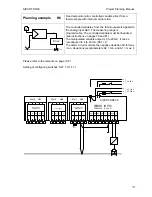

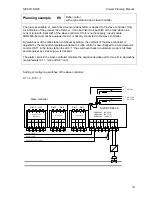

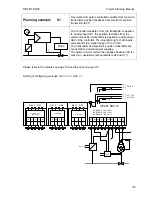

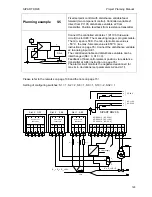

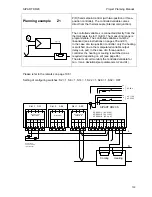

Connect the controlled variable x1 (Pt 100, three-wire

circuit) to slot AE3. The measuring range is programmable.

The min. span is 50 K, the min. start-of-scale value is

- 50

°

C, the max. full-scale value is 850

°

C (see

instructions on page 76). Connect the disturbance variable

x2 to analog input AE1.

The controlled variable and disturbance variable can be

interchanged (S8 = 0, S10 = 0).

Feedback of final control element position via resistance

transmitter at AE4 (instruction on page 76).

The alarm circuit monitors the negative deviation xd for

max./min. deviations (set parameters A2 and A1 !).

Please refer to the remarks on page 108 and the note on page 15 !

Setting of configuring switches: S1 = 1, S2 = 2, S8 = 1, S9 = 1, S10 = -2, S32 = 1

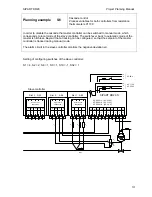

AE1

AE2

BE

BA

L+

GND GND

L

1

2

3

4

5

6

7

8

SIPART DR20 S

6DR2001-1 (AC 230 V)

6DR2001-2 (AC 115 V)

6DR2001-4

(UC 24 V)

1

2

3

4

1

2

3

4

1

2

3

4

PE

N

L

AC 115 V

AC 230 V

⎫

⎬

⎭

PE

N

UC 24 V

L

⎫

⎬

⎭

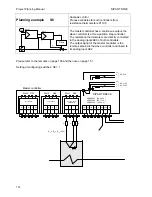

Slot 3 GW

Slot 2 AE4

Slot 1 AE3

-

∆

y

+

∆

y

9

10

5

M1

A1

R1

A2

M2

Option module

6DR2800-8R

Option module

6DR2801-8A

M

M/A

S

E

L

N

I

R

E

R

A

S

R = R

A

+

∆

R + R

E

Power supply

+

-

Option module

6DR2800-8P

R

L3

R

L4

Pt100

R

L1

R

L1

= R

L3

= R

L4

≤

50

Ω

129