Project Planning Manual

SIPART DR20

2.

The SIPART DR20 Controller

2.1 Application

The SIPART DR20 is a stand-alone process controller for a wide range of applications in process

engineering, mechanical engineering and apparatus engineering. It is available in the following

designs:

•

K controller with continuous output

for connection of pneumatic or hydraulic actuators with proportional action

•

S controller with step output,

programmable either as:

-

three-position step controller for electric actuators

-

two-position controller with two outputs for heating and cooling

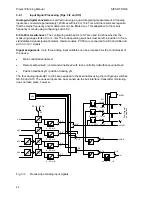

Its flexibility means that SIPART DR20 is suitable for designing simple control loops as well as for

solving control tasks in meshed controls. It can be used in conventional parallel wiring via its

analog and digital interfaces. In addition, it can be connected to higher-level systems (process

computers or control systems) via an addressable serial interface which can be retrofitted at any

time or incorporated into a central operating and monitoring system with a personal computer and

the SIPART software, if applicable also together with devices from the TELEPERM D range.

The SIPART DR20 can be programmed to the most common types of controller:

•

Fixed setpoint controller with and without disturbance variable feedforward at

input and output

•

DDC backup fixed setpoint controller

•

Follow-up controller with and without local/remote switchover (SPC)

•

Synchronization controller for controlled variable

•

Ratio controller

In addition, the device can also be used as a ratio station, manual/automatic control station (also

DDC manual control station) and process indicator.

The control and display unit (front module) of the SIPART DR20 is sealed by a plastic foil so that

degree of protection IP 64 is possible with a suitable installation configuration. The mounting depth

of the device is very small so that it is not only suitable for panel and switchboard mounting but

also for direct installation in machines and equipment.

An extremely high reliability for the device has been achieved by extensive and expensive

measures during development and manufacture. In addition to appropriate selection of the

components used, a worst-case design of the circuits and a 24-hour burn-in with subsequent

computer-controlled final test, special measures have been included to provide an interference-free

design of the circuits and high noise immunity towards RF sources.

10