5 - 12

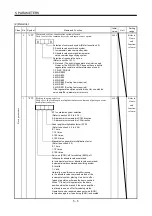

5. PARAMETERS

Class No. Symbol

Name and Function

Initial

value

Unit

Setting

range

31

MO1 Analog monitor 1 (MO1) offset

Used to set the offset voltage of the analog monitor 1 (MO1) output.

0 mV 999 to

999

32

MO2 Analog monitor 2 (MO2) offset

Used to set the offset voltage of the analog monitor 2 (MO2) output.

0 mV 999 to

999

33 MBR Electromagnetic

brake

sequence

output

Used to set the delay time (Tb) between when the electromagnetic brake

interlock (MBR) switches off and when the base circuit is shut off.

(Refer to section 3.9)

100 ms 0

to

1000

34

GD2 Ratio of load inertia moment to servo motor inertia moment

Used to set the ratio of the load inertia moment to the servo motor shaft

inertia moment. (Refer to chapter 8)

When auto tuning is selected, the result of auto tuning is automatically set.

70

0.1

times

0 to 1000

35

PG2 Position control gain 2

Used to set the gain of the position loop. (Refer to chapter 8)

Set this parameter to increase the position response level to load disturbance.

Higher setting increases the response level but is liable to generate vibration

and/or noise.

When auto tuning is selected, the result of auto tuning is automatically set.

35 rad/s

1

to

1000

36 VG1 Speed

control

gain

1

Normally this parameter value need not be changed.

Higher setting increases the response level but is liable to generate vibration

and/or noise. (Refer to chapter 8)

When auto tuning is selected, the result of auto tuning is automatically set.

177 rad/s 20

to

8000

37 VG2 Speed

control

gain

2

Set this parameter when vibration occurs on machines of low rigidity or large

backlash. Higher setting increases the response level but is liable to generate

vibration and/or noise. (Refer to chapter 8)

When auto tuning is selected, the result of auto tuning is automatically set.

817 rad/s 20

to

20000

38 VIC Speed

integral

compensation

Used to set the integral time constant of the speed loop. (Refer to chapter 8)

When auto tuning is selected, the result of auto tuning is automatically set.

48 ms

1

to

1000

39 VDC Speed

differential

compensation

Used to set the differential compensation. (Refer to chapter 8)

Made valid when the proportion control (PC) is switched on.

980 0

to

1000

40

0

41

For manufacturer setting

Do not change this value by any means.

0

42

*ZPS Home position return position data

Used to set the current position on completion of home position return.

(Refer to section 4.4)

0

10

STM

m

32768

to

32767

43

DCT Moving distance after proximity dog

Used to set the moving distance after proximity dog in count type home

position return. (Refer to section 4.4.3)

1000

10

STM

m

0 to

65535

44

ZTM Stopper type home position return stopper time

In stopper type home position return, used to set the time from when the

machine part is pressed against the stopper and the torque limit set in

parameter No.45 is reached to when the home position is set.

(Refer to section 4.4.5)

100

ms

5 to 1000

E

xpa

n

si

on

pa

ra

m

et

ers

1

45

ZTT

Stopper type home position return torque limit

Used to set the torque limit value relative to the max. torque in [%] in stopper

type home position return. (Refer to section 4.4.5)

15

%

1 to 100

Summary of Contents for MR-J2S-10CP

Page 11: ...A 10 MEMO ...

Page 19: ...8 MEMO ...

Page 45: ...1 26 1 FUNCTIONS AND CONFIGURATION MEMO ...

Page 181: ...6 20 6 MR Configurator SERVO CONFIGURATION SOFTWARE MEMO ...

Page 207: ...7 26 7 DISPLAY AND OPERATION MEMO ...

Page 219: ...8 12 8 GENERAL GAIN ADJUSTMENT MEMO ...

Page 229: ...9 10 9 SPECIAL ADJUSTMENT FUNCTIONS MEMO ...

Page 231: ...10 2 10 INSPECTION MEMO ...

Page 249: ...12 8 12 OUTLINE DIMENSION DRAWINGS MEMO ...

Page 257: ...13 8 13 CHARACTERISTICS MEMO ...