TROUBLESHOOTING

Page 71

CYLINDER HEAD AND

CYLINDER BLOCK LEAK TEST

PROCEDURE

Verify suspected leaks in the cylinder heads or

cylinder block by pressure testing before deciding

to replace the cylinder head or block. Do not use

magnaflux inspections alone as replacement

criteria.

Before proceeding with the tests, look for coolant

stains around the 3/4-inch NPT plugs on the tops

of the cylinder heads. Check that the plugs are

torqued to 55 lb-ft (75 N•m).

Cylinder head pipe plugs used on engines

manufactured April 1, 1999 or later (beginning

with engine serial number series 9F) have

encapsulated epoxy sealant applied to the

threads. These pipe plugs are tightened to

55 lb-ft (75 N•m) at assembly, and the epoxy

locks them in place. These plugs will not turn

when an attempt is made to tighten them. If a

coolant leak at an epoxy-sealed pipe plug is

suspected, the plug may be removed by heating it

to 400

°

F (205

°

C) with a torch. Before reinstalling

the plug, the epoxy sealant must be thoroughly

cleaned from the pipe plug threads, and the

threads in the cylinder head. The plug and the

cylinder head threads must then be cleaned with

Loctite

®

Primer T and resealed with Loctite

®

277.

Reinstall the plug and torque to 55 lb-ft (75 N•m).

Also, make sure leakage is not caused by the oil

cooler or air compressor. Perform the simpler

checks first to prevent unnecessary engine

disassembly. While performing the following

tests, watch for indications of minor leaks, such

as small bubbles, that can develop into more

severe leaks during engine operation.

Cylinder Head and Head Gasket

Check — In Chassis

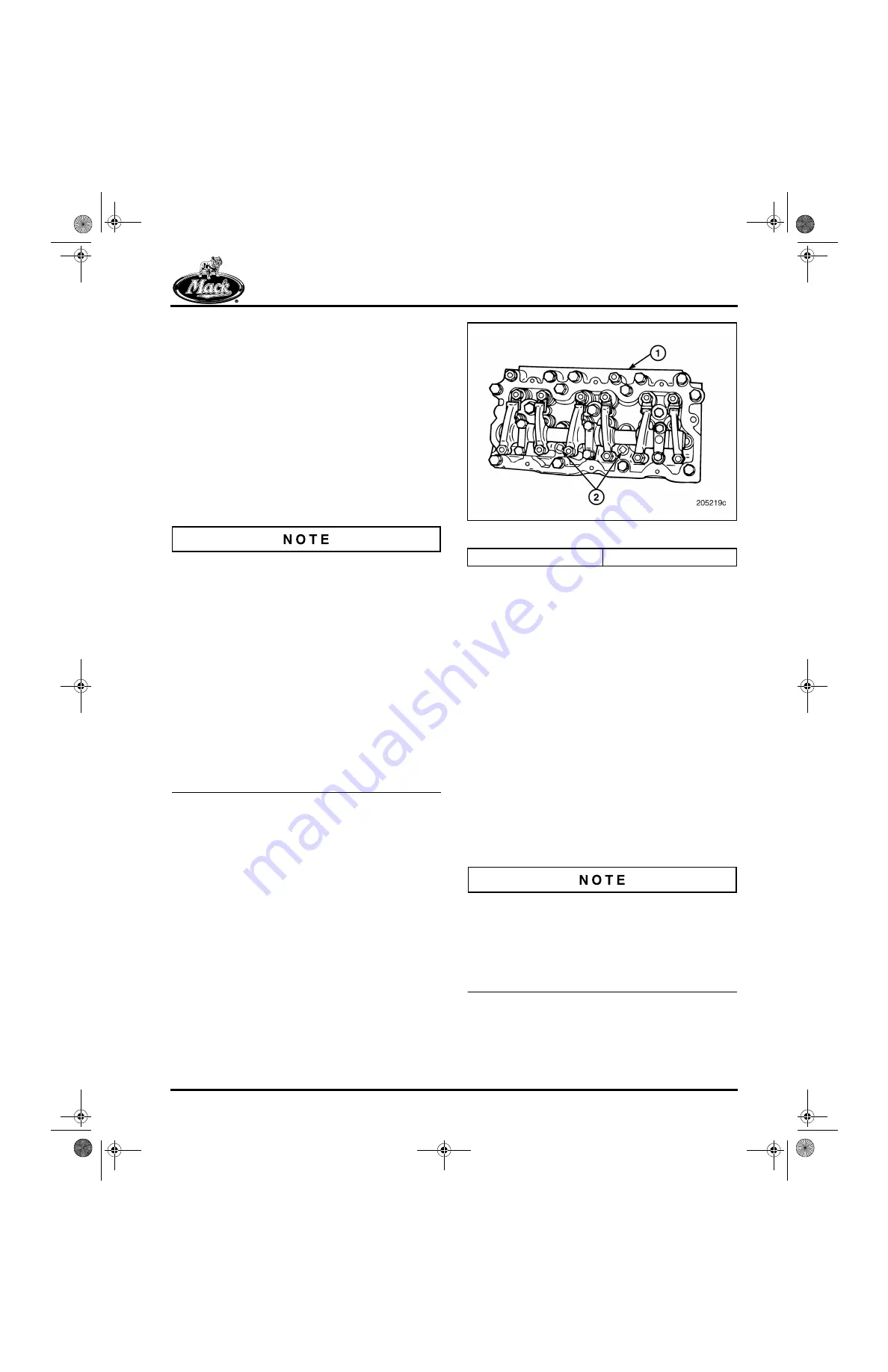

1. Look for coolant stains around the 3/4-inch

NPT pipe plugs on top of the cylinder heads.

Check plug torque. The plug torque

specification is 55 lb-ft (75 N•m). Refer to

Figure 63.

63

Figure 63 — Cylinder Head Pipe Plugs (3/4-Inch NPT)

2. Before removing the thermostat, drain

coolant from the cooling system until the

coolant level is below the thermostat

housing.

3. Remove the thermostat and leave the

thermostat housing open. Install a short

section of hose, approximately 6–8 inches

(152–203 mm) long, on the thermostat

housing and add enough coolant to fill the

housing.

4. Remove the fan belt from the water pump.

5. Start the engine and run at 1000 rpm.

6. Observe coolant in the thermostat housing

for air bubbles. This can indicate combustion

pressurization of the cooling system and

possible cylinder head gasket failure. Also,

watch for traces of oil which would indicate

possible cylinder head gasket or oil passage

leakage.

It is normal for some air bubbles to form in the

cooling system as a result of the engine warming

up to operating temperature.

The occurrence of large “gulp-type” movements

of coolant indicates a partially blocked oil cooler

inlet screen (bundle-type oil cooler only).

7. Apply a soap-and-water solution between

two cylinder heads to check for external

combustion leakage.

1. Cylinder Head

2. Pipe Plugs

5_106_00.bk Page 71 Friday, August 4, 2000 11:17 AM

BDC for engine manuals and specs