SPECIFICATIONS

Page 331

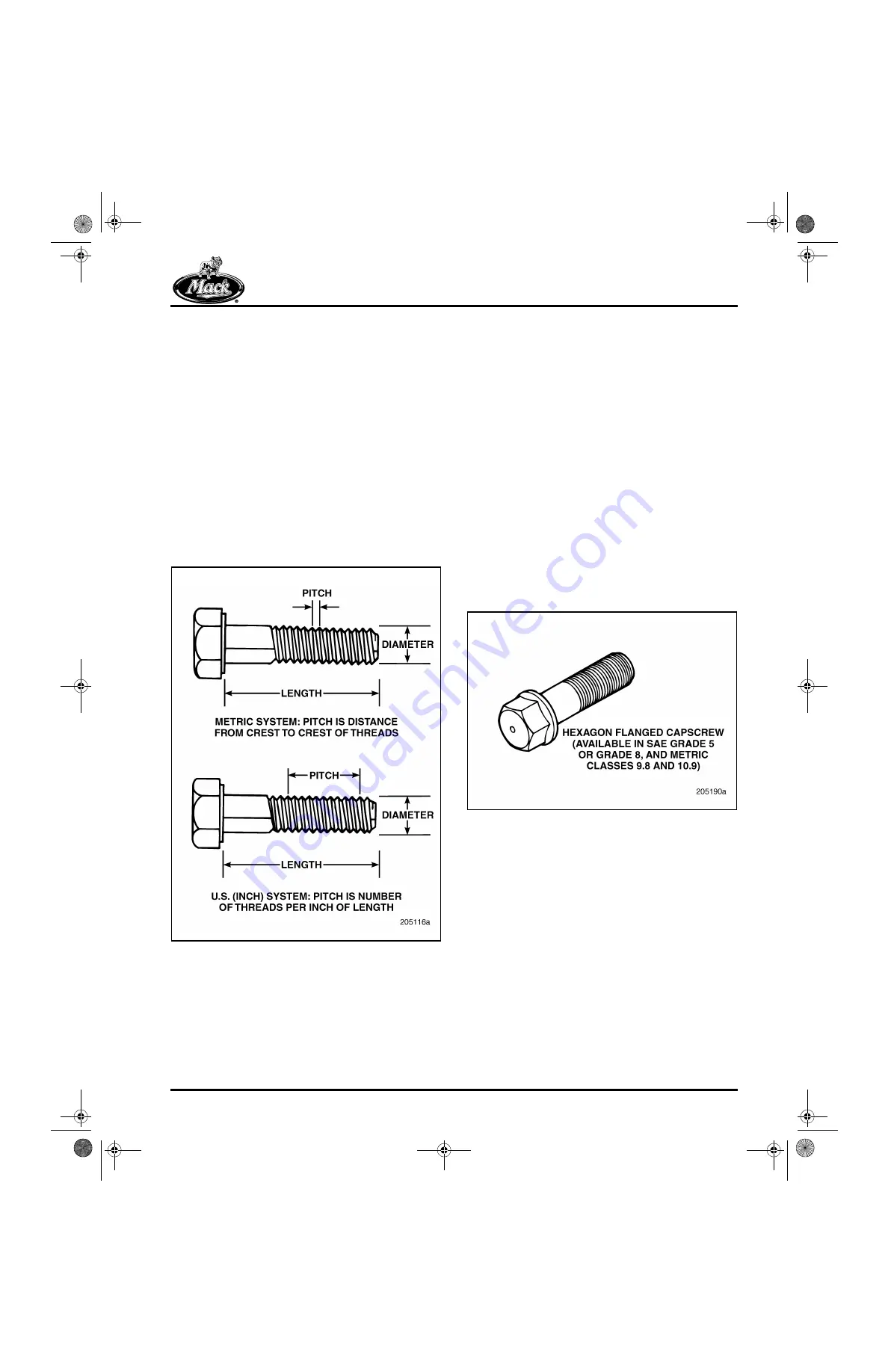

Fastener Sizes and Types

The first and most important fact that the

mechanic must know about a fastener is whether

it is a U.S. (Inch System) or a metric thread. Next,

the size of the fastener, which is usually

determined by the diameter of the shank, the

length of the fastener, which is usually measured

from the bottom of the head to the end of the

thread, and the pitch of the threads.

The pitch of U.S. (Inch System) fasteners is

measured by determining the number of threads

per inch. The two pitches commonly used in

vehicles are coarse thread, officially called

Unified National Coarse (UNC), and fine thread,

officially called Unified National Fine (UNF).

336

Figure 336 — Fastener Dimensions

The pitch of metric fasteners is measured by

determining the millimeters per thread. For

example, a bolt with 0.8 pitch would have 125

complete threads in a 100-millimeter section

(100 mm divided by 125 threads equals 0.8), and

a bolt with 1.0 pitch would have 100 threads in a

100-millimeter section. Pitch may be measured

directly, using a ruler and counting the threads.

Also, thread pitch gauges are available for both

U.S. and metric threads, which make it easy to

check the pitch of a fastener.

In the U.S. system, a typical designation would

be: 7/16-20 x 1. This describes a bolt that is

7/16 inch in diameter, has 20 threads per inch,

and is one inch long. The metric system is similar.

A typical metric designation would be: 10 x 0.8 x

25 mm. This describes a bolt that is 10 mm in

diameter, has a thread pitch of 0.8 (0.8 mm per

thread), and is 25 mm long.

337

Figure 337 — Flanged Capscrew

5_106_00.bk Page 331 Friday, August 4, 2000 11:17 AM

BDC for engine manuals and specs