Main Menu

To display the main menu and select functions, follow

these steps:

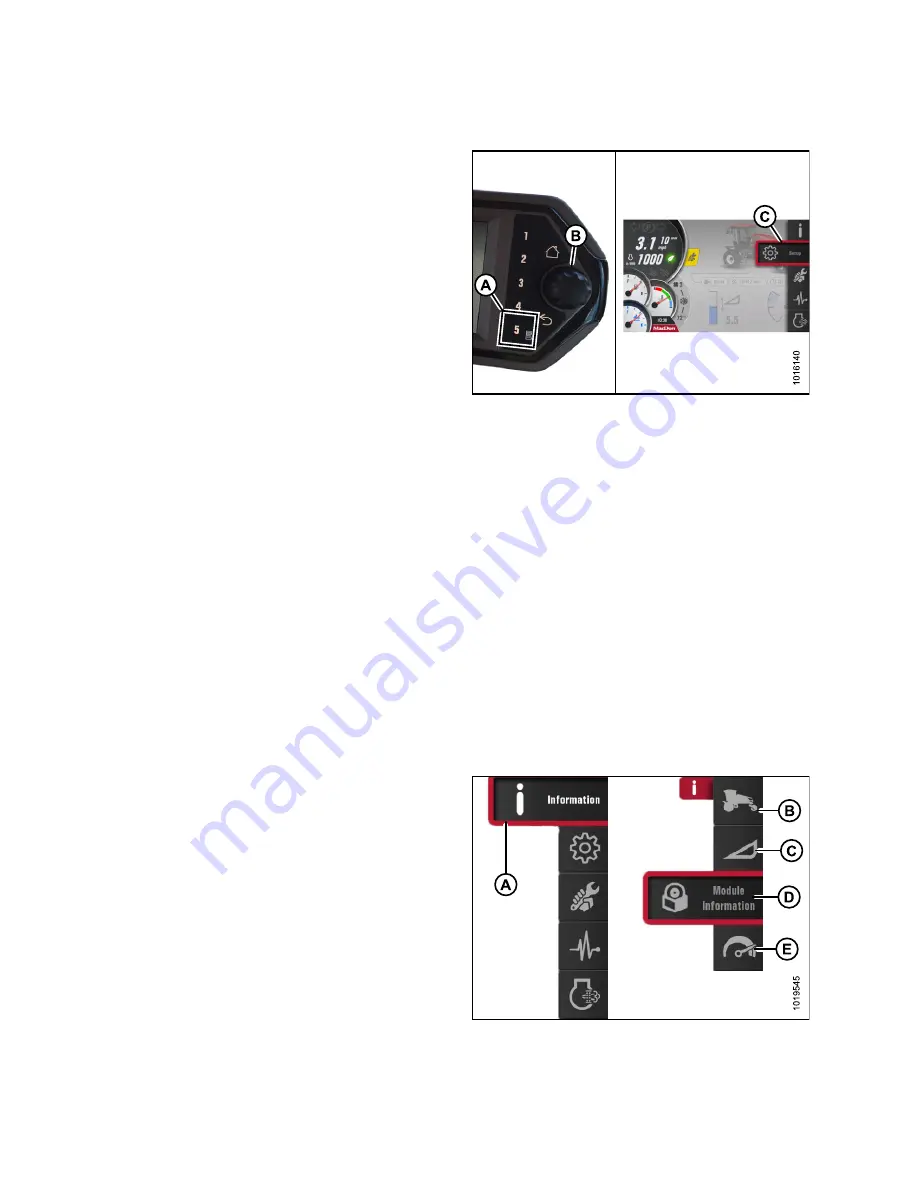

1. Press soft key 5 (A) to open the main menu.

2. Use the Harvest Performance Tracker (HPT) scroll

knob (B) or the ground speed lever (GSL) scroll wheel

(not shown) to place the red cursor (C) over the icon

you want to select.

NOTE:

Using scroll knob will activate text hints on screen

that explain each selection.

3. Press the HPT scroll knob (B) or the GSL SELECT

button (not shown) to select the highlighted icon.

NOTE:

Pressing the corresponding soft key will also work.

Figure 3.79: Opening the Main Menu

The main menu provides access to submenus for viewing and adjusting windrower and header settings. Refer to

for details on navigating the following submenus:

• Information

• Settings

• Maintenance

• Diagnostics

• Engine aftertreatment

Menu Icons

Several menu icons are available in the main menu. Selecting a menu icon will open submenu icons, menu lists,

and radio buttons for viewing and adjusting windrower and header settings.

Information:

Icon

(A)

displays

the

following

submenu icons:

• Windrower information (B)

• Header information (C)

• Module information (D)

• Performance information (E)

Figure 3.80: Information Icon and Information

Submenu Icons

214053

84

Revision A

Summary of Contents for M1240

Page 29: ...SAFETY 1 11 Safety Sign Locations Figure 1 31 Safety Sign Locations 214053 17 Revision A ...

Page 40: ......

Page 116: ......

Page 246: ......

Page 352: ...MAINTENANCE AND SERVICING Figure 5 175 Main Fuse Panel Decal MD 207815 214053 340 Revision A ...

Page 370: ......

Page 388: ......

Page 487: ......