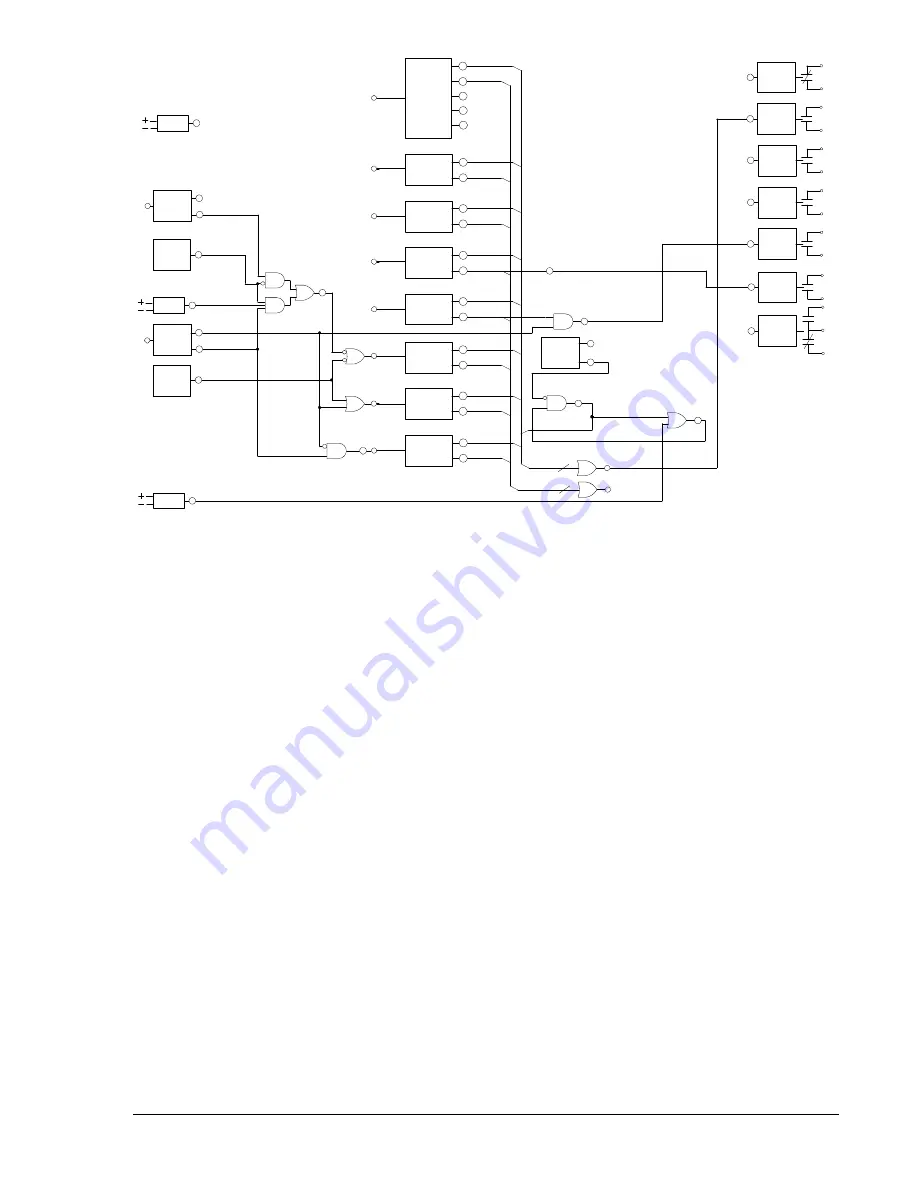

OPTO

OPTO

OPTO

D2850-06

04-29-99

9

Note: For clarity, multiple variables

going to the same OR Gate are shown

by a single line into the OR Gate.

50TN

Mode1

50TNT

50TNPU

5OTQ

Mode1

50TQT

50TQPU

BLK

BLK

8

VO11 PROT TRIP

VO12 PROT PU

VOA

Relay

Trouble

OUTA

Output

Logic

VO1

Motor

Trip

OUT1

Output

Logic

VO2

Not Used

OUT2

Output

Logic

VO3

Not Used

OUT3

Output

Logic

VO4

Overload

Alarm

OUT4

Output

Logic

VO5

Unbalance

Alarm

OUT5

Output

Logic

VO6

Not Used

Output

Logic

VO15

Unbalance

Alarm Point 23

OUT6

87

Mode1

87RT

87RPU

BLK

87UT

2NDHAR

5THHAR

143

Speed

Switch

Enable

143

IN1

Breaker1

Status

IN3 Emergency Trip

51Q

Mode1

51QT

51QPU

51P

Mode1

51PT

51PPU

BLK

BLK

151P

Mode1

151PT

151PPU

150TP

Mode1

150TPT

150TPPU

BLK

BLK

251P

Mode1

251PT

251PPU

BLK

VO14

Overload

Alarm Point 22

VO13

Emergency Trip

Alarm Point 21

HMI

TRSTKEY

ARSTKEY

VO9

Emergency Trip

Seal In

243

High/Low

Inertia Select

243

VO7

Starting

High Inertia

VO8

Starting

250TP

Mode1

250TPT

250TPPU

BLK

IN2

Speed Switch

Closed At Rest

50TP

Mode1

50TPT

50TPPU

BLK

LEGEND:

87 = Differential Fault Protection

50TN = BU Ground Fault Protection

50TQ = Loss Of Phase Protection

51Q = Unbalance Protection

51P = Overload Protection

151P = Locked Rotor (High Inertia)

150TP = Locked Rotor (Low Inertia)

251P = Jam Protection

50TP = Start Detection (High Inertia)

250TP = Start/Running Detection

Figure 8-14. Typical Logic Diagram for CDS240-MOTR-A-BE

Protection Elements

Referring to Figure 8-13, the 87, 50/51, 150/151, and 250 protection elements are connected to CT Input

1, and the motor side of the 87 protection element is connected to Input 2. The 87, 50/51, 150/151, and

250 protection elements are logic enabled to provide a trip by the settings shown in Table 8-31.

Protection elements set at 0 are setting disabled, and will not provide a trip output even if logic enabled.

Typically, the 87 protection element provides high-speed, percent restrained, phase and ground

protection, for faults inside the differential zone. For the CDS240-MOTR-A-BE application shown in Figure

8-14, the percent-restrained differential protection function is the only function of the 87 protection

element required. Set the pickup of the 2

nd

, 5

th

, and 87U functions to 0 (setting disabled). The

unrestrained differential function has a setting only when the 2

nd

and 5

th

harmonic restraint functions are

set for transformer applications (refer to the discussion in

Overview Of Preprogrammed Logic Schemes

).

In the CDS240-MOTR-A-BE scheme, the 50TQ protection element is used for loss of phase detection,

the 51Q protection element is used for unbalance protection (46), and the 50TN protection element is

used for ground fault backup protection.

In the CDS240-MOTR-A-BE scheme, the 51P protection element is used for motor overload protection.

Blocking during starting is not required since this element is slower than the locked rotor protection. It also

serves as backup during starting. The 251P protection element is used to protect for a jam or stall

condition. It is blocked while the motor is starting as determined by VO8.

In the CDS240-MOTR-A-BE scheme, the 150TP protection element provides locked rotor protection for

low inertia motors. It is blocked when the motor is running (after the 250TP time setting expires) or when

Virtual Control Switch 243 is set to high inertia mode. The 151P protection element provides locked rotor

protection for high inertia motors. It is blocked when Virtual Control Switch 243 is set to low inertia mode.

9365200990 Rev F

BE1-CDS240 Application

8-47

Summary of Contents for BE1-CDS240

Page 2: ......

Page 8: ...vi BE1 CDS240 Introduction 9365200990 Rev F This page intentionally left blank ...

Page 38: ...1 28 BE1 CDS240 General Information 9365200990 Rev F This page intentionally left blank ...

Page 40: ...ii BE1 CDS240 Quick Start 9365200990 Rev F This page intentionally left blank ...

Page 152: ...ii BE1 CDS240 Metering 9365200990 Rev F This page intentionally left blank ...

Page 226: ...iv BE1 CDS240 Application 9365200990 Rev F This page intentionally left blank ...

Page 286: ...ii BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 290: ...9 4 BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 292: ...ii BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 306: ...10 14 BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 308: ...ii BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 342: ...11 34 BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 349: ...Figure 12 5 Horizontal Rack Mount Front View 9365200990 Rev F BE1 CDS240 Installation 12 5 ...

Page 361: ...Figure 12 17 Typical DC Connection Diagrams 9365200990 Rev F BE1 CDS240 Installation 12 17 ...

Page 372: ...12 28 BE1 CDS240 Installation 9365200990 Rev F This page intentionally left blank ...

Page 468: ...13 92 BE1 CDS240 Testing and Maintenance 9365200990 Rev F This page intentionally left blank ...

Page 512: ...14 42 BE1 CDS240 BESTCOMS Software 9365200990 Rev F This page intentionally left blank ...

Page 544: ...ii BE1 CDS240 Terminal Communication 9365200990 Rev F This page intentionally left blank ...

Page 550: ...ii BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 578: ...D 28 BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 579: ......