Rostock MAX v2 Assembly Guide

The

Lines

infill pattern differ from the others in that the line orientation is alternated every

other layer. All the examples show a 20% infill density.

You're probably wondering which infill pattern is “best”. I wish I could go into that, but I've

been unable to locate any studies that cover the topic in any depth. If I were asked to provide a

recommendation for a good structural pattern I would probably pick the

Triangles

option. It offers a

good internal structure for most infill densities that I've used it with.

Skirt and Brim

– This is a new option that appears with the

Intermediate

and

Advanced

setting levels. The

Skirt

option is used one of two ways. First, it can be used to “prime” the hot end

with filament before the actual part itself begins to print. You may notice that your hot end may

“drool” filament while the bed is heating up and the hot end has already reached temperature. This is

perfectly normal. However, without some kind of priming action, early features of your part may not

print properly. The

Skirt

solves this. Secondly, the

Skirt

can become a

Brim

if the

Distance from

Object

setting is set to zero. What this does is make sure that the skirt is physically connects to the

part, becoming a brim. This can be handy when you're printing a small part and you're having bed

adhesion issues and you don't want to have to use a raft. Later on in the

Advanced

settings section,

you'll see more options on how you can tweak the

Skirt and Brim

settings.

Support Material

– With the

Intermediate

and

Advanced

setting levels, you get more control

over how the support material for your part is generated.

The new option here is called

Support Type

and allows you to choose a

LINES

or

GRID

pattern for the support material. When I printed the support example, I used the

LINES

mode as that is

the default for the

Simple

settings mode. Looking down on it from above, this is what the

LINES

support material pattern looked like for that print.

This shows the second layer of the print. The lines will continue to stack upon

one another for the entirety of the support structure.

267

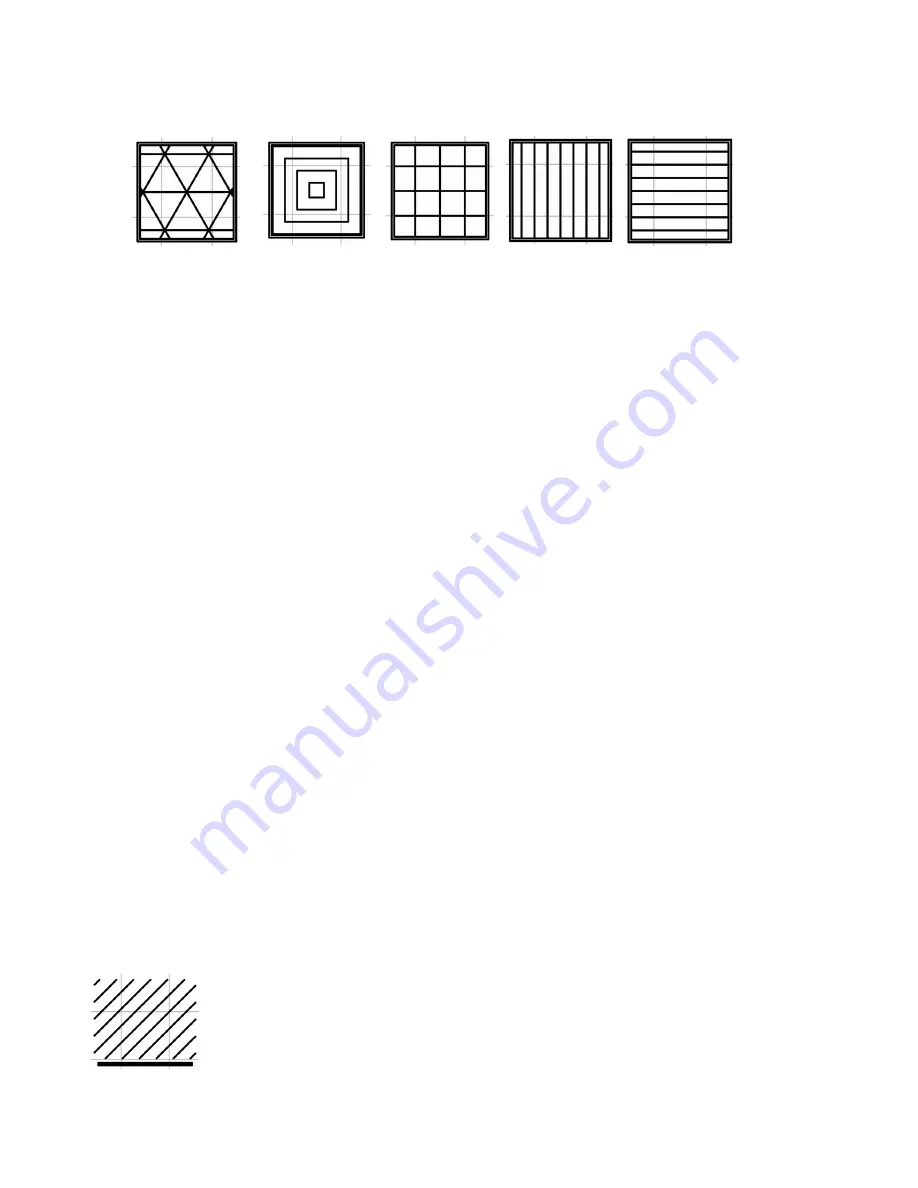

Triangles

Lines #1

Concentric

Grid

Lines #2

Summary of Contents for Rostock MAX v2

Page 25: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 1 25 ...

Page 26: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 2 Melamine Parts Sheet 3 26 ...

Page 27: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 4 27 ...

Page 171: ...Rostock MAX v2 Assembly Guide 171 Fig 14 8 Spool holder support installed ...