Rostock MAX v2 Assembly Guide

The problem with troubleshooting is sometimes trouble shoots back. :)

Your Rostock MAX v2 3D printer is a pretty complex piece of machinery even though it looks

pretty simple. As with any complex device sometimes things can go wrong in really weird ways. This

won’t be a comprehensive troubleshooting guide, but will touch on a few of the problems I’ve run into

with my printer. As others offer tips, they’ll be added to this section.

Print Layer Issues

When you first start a print, you should get a very even and consistent layer height. By properly

adjusting the machine, you should get this automatically if you’ve got all three towers adjusted exactly

the same. Unfortunately, that’s really difficult to do. The larger the object you print, the more obvious

first layer thickness inconsistencies will be, especially when using loops.

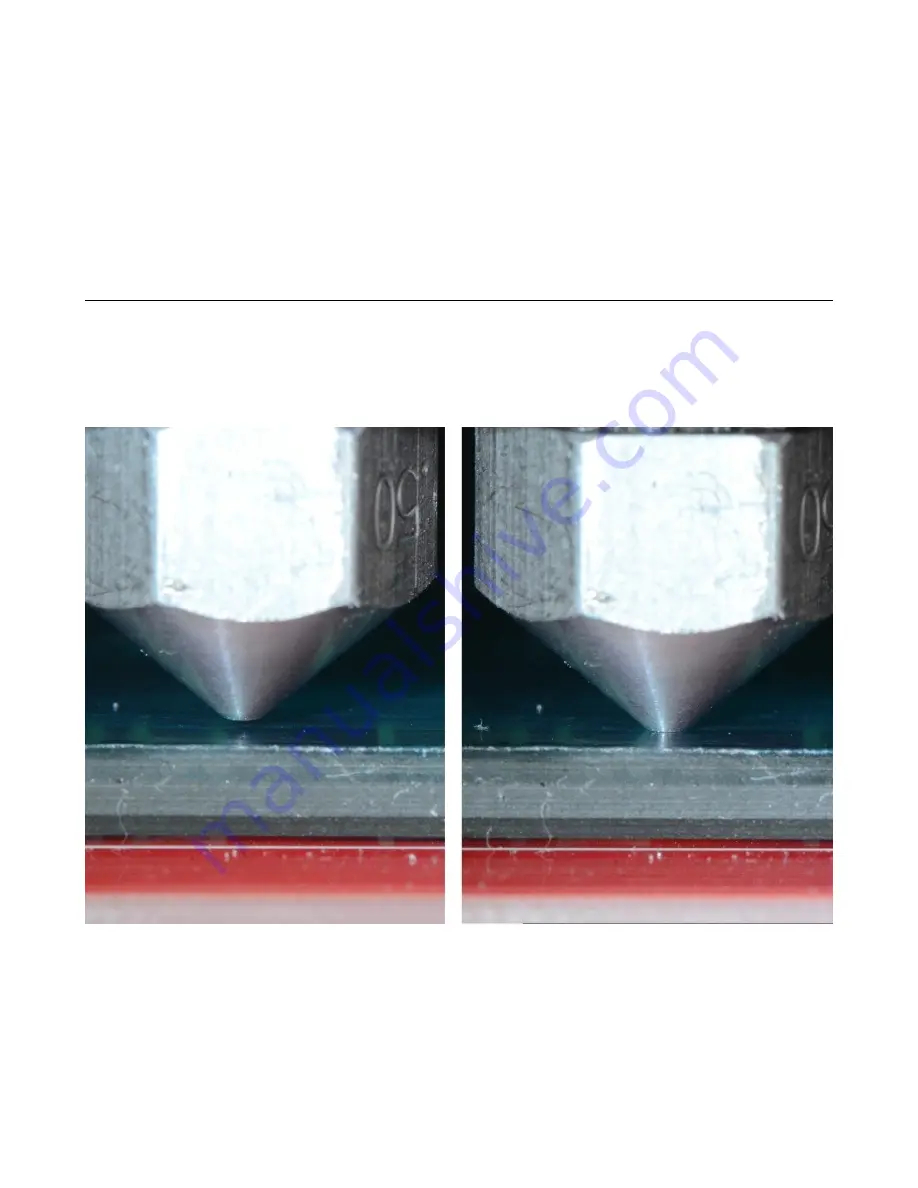

Above is an example of correct and incorrect nozzle height. The nozzle on the right is right at

the surface of the print bed. This means that there’s no room for the plastic to go – the bed is effectively

plugging the nozzle and will eventually cause the extruder to start skipping, or it'll grind a notch in the

filament as it tries to feed it.

311

Fig. A-1: Nozzle height examples. (Image Courtesy of LulzBot)

Summary of Contents for Rostock MAX v2

Page 25: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 1 25 ...

Page 26: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 2 Melamine Parts Sheet 3 26 ...

Page 27: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 4 27 ...

Page 171: ...Rostock MAX v2 Assembly Guide 171 Fig 14 8 Spool holder support installed ...