Rostock MAX v2 Assembly Guide

In the figure to the right, you'll see the control panel for the extruder. In order to safely feed the

hot end, make sure that you've selected “10” in the settings below the

E+

button. Click the

E+

button

to begin feeding filament through the hot end. You may have to click the button a number of times to

get filament coming out of the hot end, but you'll want to wait for the extruder to stop moving before

you click it again.

Once it does begin to feed, go ahead and click the

E+

button a few more times just to get the

extruder all nice and primed.

I recommend that you extrude 20-30mm of filament each time you start up the printer for the

day. This ensures that the hot end is primed and you have no jamming issues.

Preparing the Heated Bed

ABS won't stick to bare glass. In order to get the ABS to stick, you're going to need to apply

two thin layers of glue to the bed. Remember back in the “need to have” list, I listed the Elmer's

“Disappearing Purple” glue stick? This is where you're going to use it.

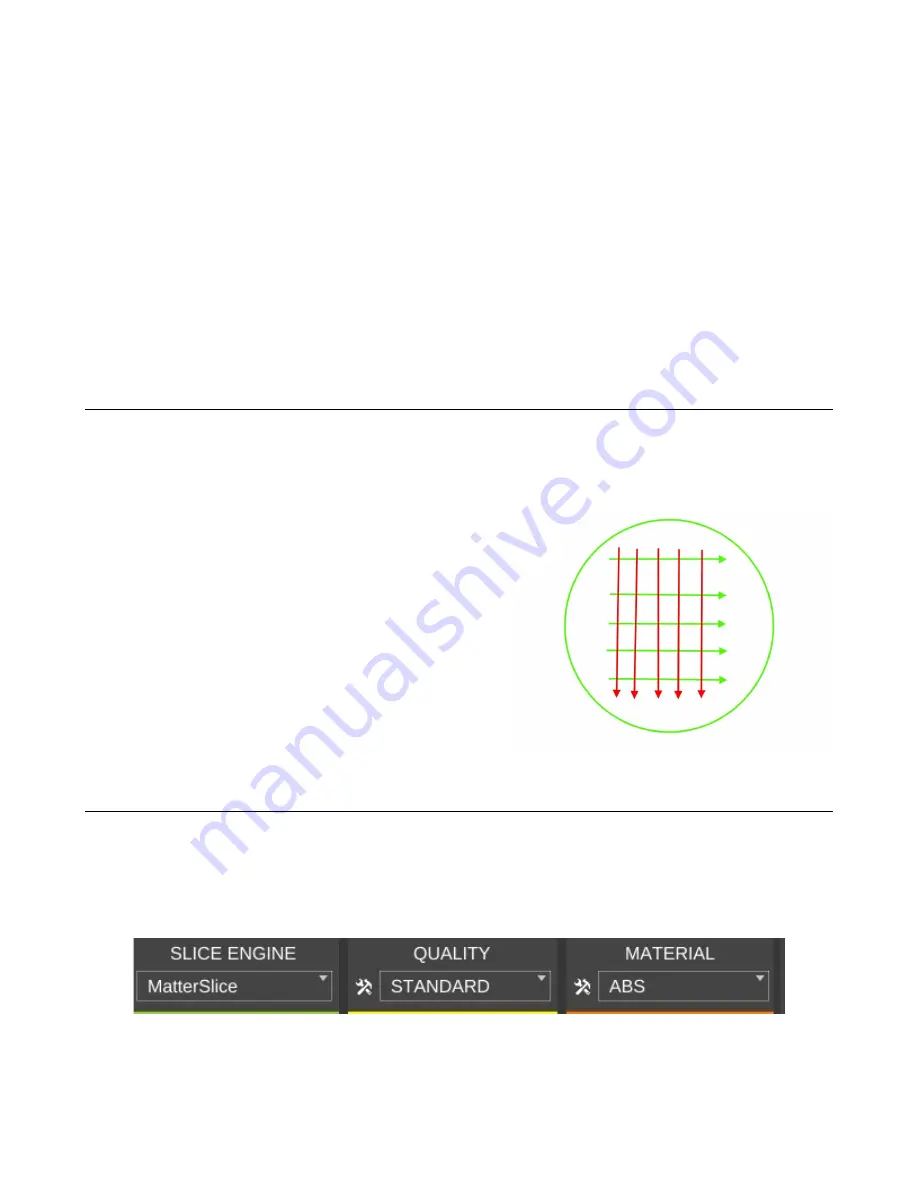

You'll want to apply two perpendicular layers of

glue on to the heated bed. Follow the simple pattern in

Fig. 20-16. The green lines represent the first layer and

the red lines represent the second. The idea is to lay down

a thin, even layer with no spaces between each “lane” of

glue. Let the base layer completely dry before applying

the second layer. Let THAT layer dry before starting a

print.

Printing the PEEK Fan Shroud

Check on the

Slice Settings

pane to make sure that you've got “MatterSlice” chosen for the

slice engine, “STANDARD” chosen for Quality, and “ABS” chosen for Material.

Make sure that the

filament you have loaded in your printer IS ABS! Running PLA at ABS temperatures without the

PEEK fan installed will cause the hot end to jam!

Now that you've gotten everything loaded and prepped, starting the print is as simple as clicking

250

Fig. 20-16: Glue application.

Fig. 20-17: Correct slice settings.

Summary of Contents for Rostock MAX v2

Page 25: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 1 25 ...

Page 26: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 2 Melamine Parts Sheet 3 26 ...

Page 27: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 4 27 ...

Page 171: ...Rostock MAX v2 Assembly Guide 171 Fig 14 8 Spool holder support installed ...