Rostock MAX v2 Assembly Guide

the extrusion width. This means that each new layer has a solid foundation to adhere to as it's being

applied.

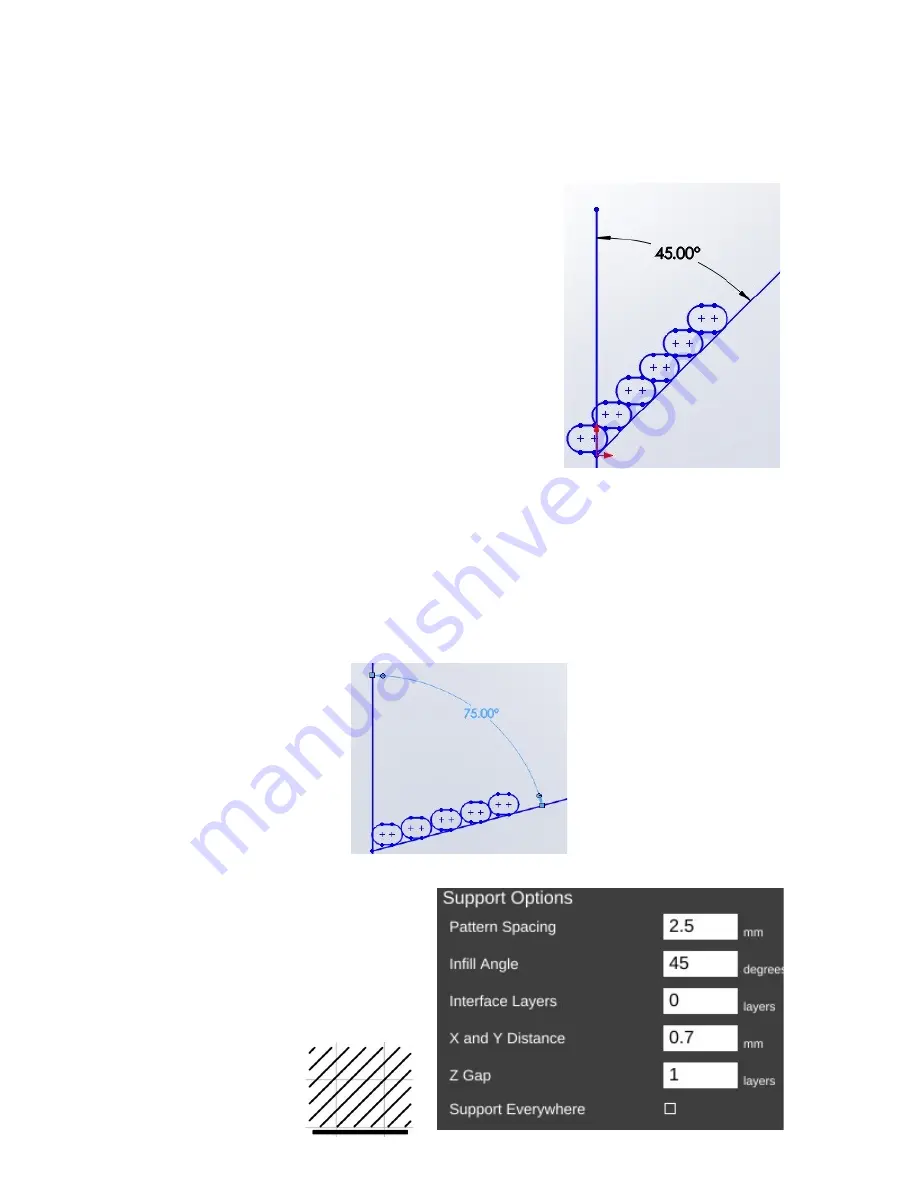

As you can see when your angle increases to 45 degrees,

each layer has much less surface area to adhere to as you print.

This is where support comes in handy. It provides that underlying

structure for those layers to build upon.

As the angle increases, the underlying surface area for each layer becomes smaller and smaller

until there's simply not enough surface for the next layer to adhere to. In these instances, support

material is practically a requirement if you want your part to print at all.

Now that you've got a good handle on why support can be useful, let's go over the parameters

that you can tune to get good support that is easily removable from your part.

Pattern Spacing

controls the distance

between each “track” of support that is laid

down to support your part. The wider the

spacing, the less support that is printed.

Infill Angle

adjusts the angle at which

the support structure is built.

291

45 Deg. Infill

Fig. 25-6: 45 deg. overhang.

Fig. 25-7: 75 deg. overhang.

Summary of Contents for Rostock MAX v2

Page 25: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 1 25 ...

Page 26: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 2 Melamine Parts Sheet 3 26 ...

Page 27: ...Rostock MAX v2 Assembly Guide Melamine Parts Sheet 4 27 ...

Page 171: ...Rostock MAX v2 Assembly Guide 171 Fig 14 8 Spool holder support installed ...