Operation

Page 5-8

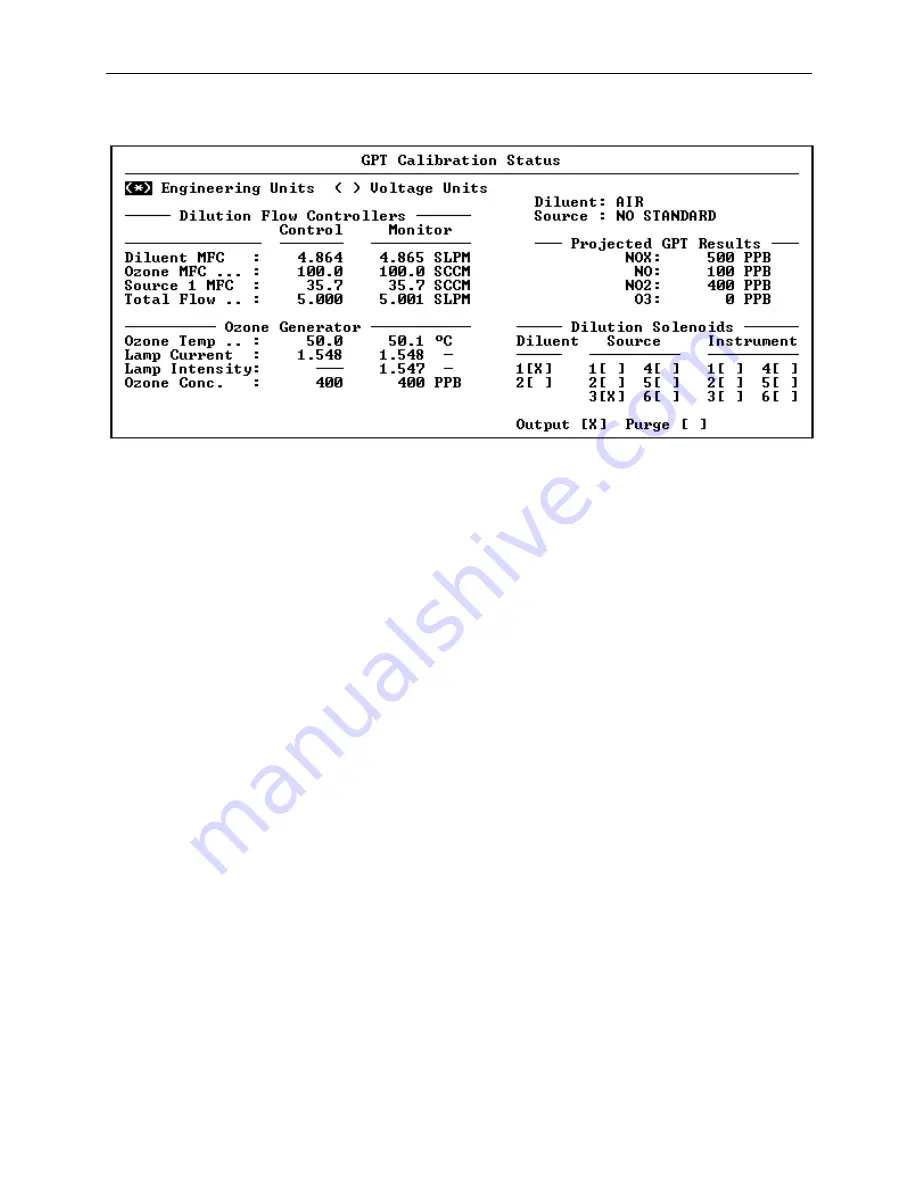

Figure 5-7 The GPT Status Screen

Performing Manual Calibrations using the Status Screen

Normally, when a status screen is displayed, the only item that

can be changed is the engineering or voltage units selector

button, however by entering debug mode, any of the control

values or solenoid valves may be changed. This is a very useful

feature, allowing devices to be tested individually or manual

calibrations to be performed. Debug mode is toggled on or off

by pressing the "Diag." Button on the front panel or F11 on an

external keyboard while the status screen is displayed.

Before performing calibrations using debug mode, it is important

that the user has a good understanding of the pneumatic

operation of the

2010D

and the purposes of it's various flow

controllers and solenoid valves. In this mode, it is entirely

up to the user to manually activate the appropriate solenoid

valves, flows rates, ozone generator, etc. for the desired

result. It is also up to the user to calculate the flow rates

needed for the desired gas concentrations.

In the following example, a GPT calibration will be activated

manually using the status screen in debug mode. In the example,

a concentration of 400 PPB of ozone will be mixed with 500 PPB

of NO at a total flow rate of 5.000 SLPM, resulting in 500 PPB

of NOx, 400 PPB of NO2 and 100 PPB of excess NO. The source

cylinder, attached to source inlet 1, contains 50,000 PPB of NO.

The following steps are required to perform this calibration

using the status screen.

Summary of Contents for 2010D

Page 1: ...MODEL 2010D GAS DILUTION CALIBRATOR OPERATIONS MANUAL I N S T R U M E N T S...

Page 3: ......

Page 20: ...System Operations Page 3 2 Figure 3 1 The Model 2010D Front Panel...

Page 42: ...Installation Page 4 15 Figure 4 1 Rear Panel...

Page 63: ...Operation Page 5 7 Figure 5 5 The Dilution Status Screen Figure 5 6 The Ozone Status Screen...

Page 177: ...MODEL 2010D GAS DILUTION CALIBRATOR SCHEMATICS...

Page 178: ......