ENGINE

3.60

CRANKSHAFT/COUNTER BALANCE/OIL PUMP INSTALLATION

Lubricate all bearings with clean engine oil before assembly.

Use the crankshaft installation tool kit PN 2871283 to prevent damage to the crankshaft and main bearings during

installation.

1.

Install the crankshaft into the PTO side crankcase. Screw the threaded rod into the crankshaft until the

threads are engaged a minimum of one inch (25.4mm).

2.

Install the collar, washer, and nut onto the threaded rod. Hold the crankshaft and tighten the nut to draw the

crankshaft into the main bearings until fully seated. Loosen the nut and remove the threaded rod from the

crankshaft. If removal is difficult, install two nuts on the end of the threaded rod and tighten against each other.

3.

Install the proper shim on the magneto end of the crankshaft.

4.

Place the balancer shaft in the PTO crankcase aligning the timing marks on the crankshaft and balancer

gears. Install the proper shim washer on the shaft.

5.

Inspect the oil pump sealing surface on the crankcase. Apply a light film of engine oil to the surface and install

the oil pump.

NOTE: Do not use gasket sealer on the pump mating surfaces.

NOTE: After engine is assembled and machine is readied for field operation, oil pump MUST be primed. Follow

oil pump priming procedure on page 3.13.

6.

Align the drive gear with the drive pin on the pump shaft and install the gear. Be sure the gear is fully seated

and properly engaged.

7.

Install the proper shim washer on the pump shaft.

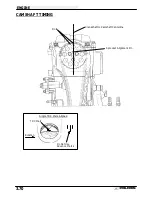

CRANKCASE ASSEMBLY

1.

Apply 3 Bond 1215 (P/N 2871557) to the crankcase mating surfaces. Be sure the alignment pins are in place.

2.

Set the crankcase in position carefully to avoid damaging the pump shaft seal, and install the magneto end

crankshaft installation tool (follow instructions provided with tool kit PN 2871283). Draw the crankcase halves

together by tightening the nut on the tool and tapping lightly in the pump shaft area with a soft faced hammer to

maintain alignment. Continually check alignment of the cases during installation, closing the gap equally until

the surfaces are tightly seated.

3.

Remove the tool.

4.

Install the crankcase flange bolts and tighten in 3 steps following the pattern on page 3.2 to specified torque.

Crankcase Sealant:

PN 2871557

Oil Pump Bolt Torque:

6. ft. lbs. (.828 kg-m)

Crankcase Bolt Torque:

14 ft. lbs. (19-20 Nm)

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...