MAINTENANCE

2.35

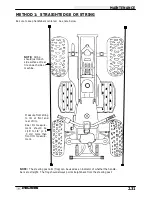

BRAKE SYSTEM INSPECTION

The following checks are recommended to keep the brake system in good operating condition. Service life of

brake system components depends on operating conditions. Inspect brakes in accordance with the maintenance

schedule and before each ride.

S

Keep fluid level in the master cylinder reservoir to the in-

dicated level inside reservoir.

S

Use Polaris DOT 3 brake fluid (PN 2870990).

S

Check brake system for fluid leaks.

S

Check brake for excessive travel or spongy feel.

S

Check friction pads for wear, damage and looseness.

S

Check surface condition of the disc.

S

Inspect thickness of brake pad friction material.

BRAKE PAD INSPECTION

S

Pads should be changed when friction material is worn

to 3/64

″

(.1 cm), or about the thickness of a dime.

HOSE/FITTING INSPECTION

Check brake system hoses and fittings for cracks, deterio-

ration, abrasion, and leaks. Tighten any loose fittings and

replace any worn or damaged parts.

Parking Brake

Lock

Sight

Glass

Min

Max

3/64

″

(.1cm)

Minimum

Thickness

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...