ELECTRICAL

10.23

ARMATURE TESTING

1.

Remove armature from starter casing. Note order

of shims on drive end for reassembly.

2.

Inspect surface of commutator.

Replace if

excessively worn or damaged.

3.

Using a digital multitester, measure the resistance

between each of the commutator segments. The

reading should be .3 ohms or less.

4.

Measure

the

resistance

between

each

commutator segment and the armature shaft. The

reading should be infinite (no continuity).

5.

Check commutator bars for discoloration. Bars

discolored in pairs indicate shorted coils, requiring

replacement of the starter motor.

6.

Place armature in a growler. Turn growler on and

position a hacksaw blade or feeler gauge

lengthwise 1/8

″

(.3 cm) above armature coil

laminates.

Rotate armature 360

°

.

If hacksaw

blade is drawn to armature on any pole, the

armature is shorted and must be replaced.

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

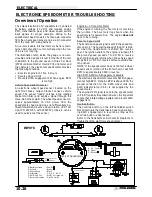

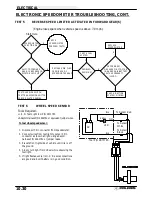

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...