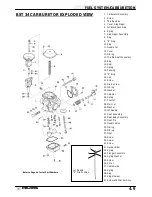

FUEL SYSTEM/CARBURETION

4.16

NEEDLE AND SEAT LEAKAGE TEST

1.

Install the float bowl. Invert the carburetor and install a

Mity-Vac

™

(PN 2870975) to the fuel inlet fitting. Apply

5 PSI pressure to inlet fitting. The needle and seat

should hold pressure indefinitely. If not, inspect needle

and seat and seat O-ring.

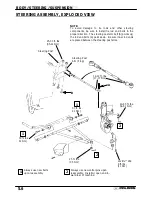

FUEL LEVEL

A fuel level test can be performed on some models if the

drain hose fitting is accessible. Be sure to re-attach the

bowl drain hose after performing the test. A fuel level test

allows you to observe the height of the fuel in the float bowl

without removing the carburetor. The fuel level can be ob-

served with the engine either running or shut off, however,

engine must run briefly to allow fuel level to stabilize..

1.

Attach a clear line to drain fitting. Be sure line fits tightly

on fitting. Position hose along side of carburetor as

shown.

2.

Open bowl drain screw by turning counterclockwise

approximately two turns. Start and run engine for 3 to 5

seconds to allow fuel level to stabilize in the line. If level

is out of specification, remove carburetor and inspect

inlet needle and seat, float height, passages, etc.

3.

If a line was removed to perform this procedure, it must

be replaced.

Mity Vac

™

PN 2870975

1.5 mm

.060

″

Bowl Mating

Surface

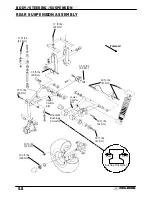

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

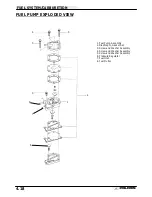

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...