ELECTRICAL

10.15

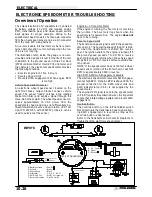

CHARGING SYSTEM TESTING

Whenever charging system problems are suspected, proceed with the following system check.

Check for owner modification, and

discuss operating habits. The battery

will continually discharge if operated

below the “Break Even” RPM. Con-

tinued problems would call for battery

inspection.

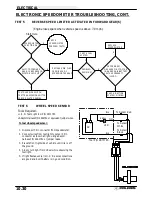

Disconnect the Yellow/Red, Yellow, and Yel-

low/Brn (if applicable) wires from the regula-

tor/rectifier. Using a multitester, perform an

Alternator Output (AC amp) test. See

test procedure on page 10.17 for proce-

dure.

Is output above 5 amps?

Inspect the wiring harness be-

tween the panel and the stator for

damage. If no damage is found,

remove the recoil and flywheel.

Inspect the flywheel magnets, sta-

tor coils and stator wire harness

for damage. Repair or replace

any damaged components.

Reconnect the alternator wires. Note: Red

wire must be connected to harness. Battery

voltage must be present on red wire terminal

on harness side of voltage regulator connector.

Is it?

Check regulator/rectifier connections

and ground, battery connections, cir-

cuit breaker and connecting wires.

Repair or replace faulty wiring or

components.

If all of the previous tests indicate a

good condition, but the charging voltage

does not rise above battery voltage at the

connector or terminal board, replace the

voltage regulator.

No

Yes

No

Yes

Perform system “Break Even Amperage”

test outlined on page 10.16.

Does charging occur as specified?

Using a multitester set on D.C. volts, mea-

sure the battery open circuit voltage (See

page 10.12). It should be 12.4 volts or

more. Is it?

Remove the battery and properly ser-

vice. Reinstall the fully charged battery

or a fully charged shop battery.

With the transmission in neutral, start the

engine and increase RPM to between 3000

and 4000. Read battery voltage with the

multitester. Readings should increase to be-

tween 13.0 and 14.6 V D.C. Are they?

No

Yes

No

Yes

Check Key off Current Draw

No

Meter Setting: AC Amps

Meter Setting: DC Amps

Meter Setting: DC Volts

Meter Setting: DC Volts

Yes

Ohm stator wire (Y/YR) If bad replace, if good,

continue with alternator output test.

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...