MAINTENANCE

2.18

COMPRESSION TEST

NOTE: 4-Stroke engines are equipped with an automatic decompressor. Compression readings will vary in pro-

portion to cranking speed during the test. Average compression (measured) is about 50-90 psi during a compres-

sion test.

Smooth idle generally indicates good compression. Low engine compression is rarely a factor in running condition

problems above idle speed. Abnormally high compression can be caused by a decompressor malfunction, or

worn or damaged exhaust cam lobes. Inspect camshaft and automatic decompression mechanism if compres-

sion is abnormally high.

A cylinder leakage test is the best indication of engine condition on models with automatic decompression. Follow

manufacturer’s instructions to perform a cylinder leakage test. (Never use high pressure leakage tester as crank-

shaft seals may dislodge and leak).

ENGINE MOUNTS

Inspect rubber engine mounts (A) for cracks or damage.

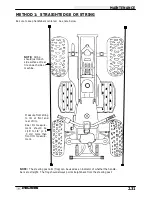

FASTENER TORQUE - ENGINE

Check engine fasteners and ensure they are tight.

Cylinder Compression

Standard

50-90 PSI

Cylinder Leakage

Service Limit

10 %

(Inspect for cause if leakage exceeds 10%)

A

A

A

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...