5. Follow Up

TSα Series User Manual 103

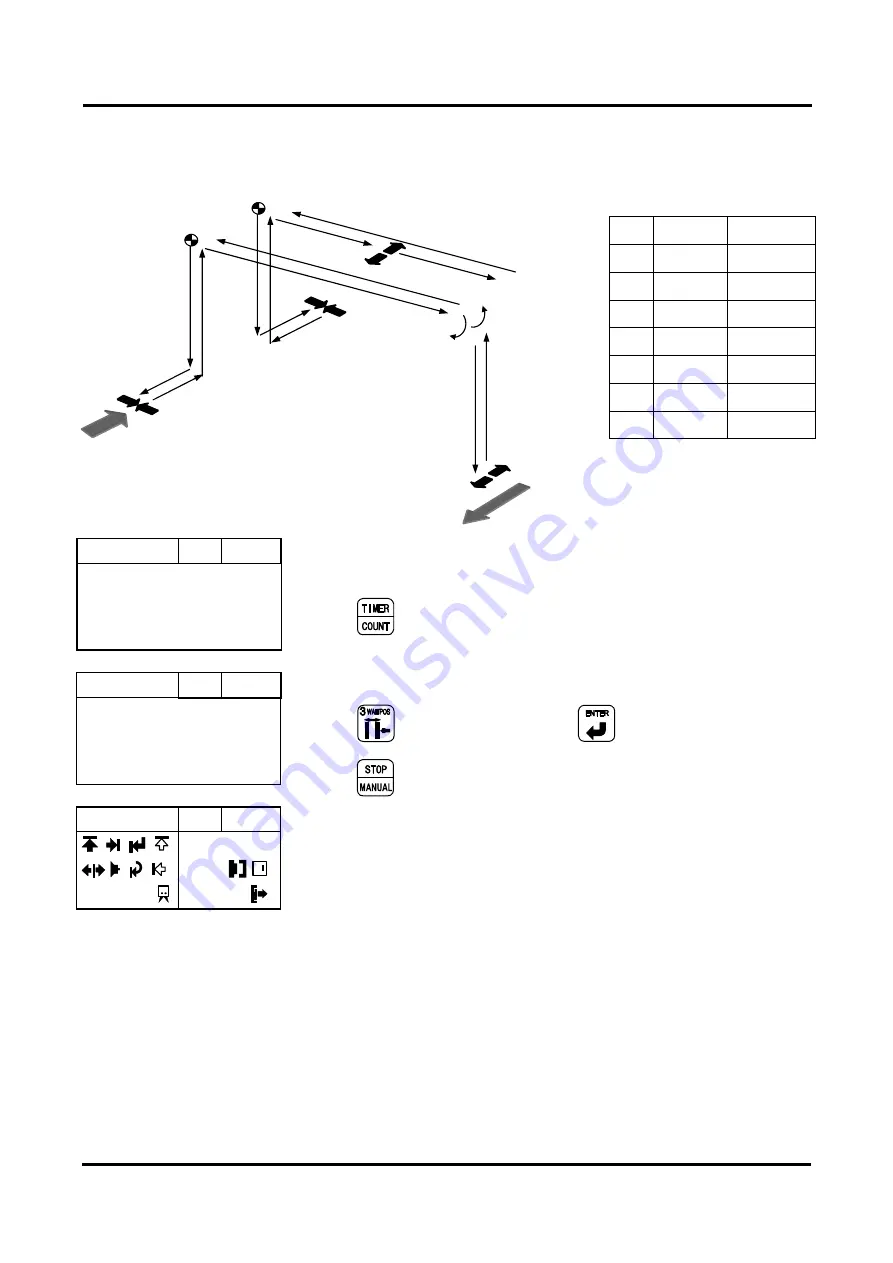

5.6 Timer Setting

z

STEP 19

[Move to timer screen, set T0 chuck delay 0.3 sec]

Press

, move to timer screen.

z

STEP 20

Press

and input 0.3sec, Press

to save data.

Press

, move to Manual Mode.

NO

Default

Display

T0

0 sec

Kick

T1

0 sec

Chuck

T2

0 sec

KicRt

T3

0.5 sec

S-Off

T4

0.3 sec

M-Off

T5

0.3 sec

UpDly

T11

5 sec

Conve

>T0 Kick 0.0 < 0.0

T1 Chuck 0.0 0.0

T2 KicRt 0.5 0.0

Timer

720

T0

T3

T2

T1

Sub Arm

Main Arm

T4

T5

Conveyor

T11

Ejector

>T0 Kick 0.3 < 0.3

T1 Chuck 0.0 0.0

T2 KicRt 0.5 0.0

Timer

◀30%▶

Manual

720

720

Summary of Contents for TS-200DI

Page 2: ......

Page 14: ...xii...

Page 15: ...xiii...

Page 19: ......

Page 20: ......

Page 21: ...1 Introduction...

Page 22: ......

Page 28: ......

Page 29: ...2 Before Operation...

Page 30: ......

Page 41: ...3 START UP STOP...

Page 42: ......

Page 47: ...4 OPERATION...

Page 48: ......

Page 114: ......

Page 115: ...5 Follow Up...

Page 116: ......

Page 126: ......

Page 127: ...6 Error...

Page 128: ......

Page 134: ......

Page 135: ...Appendix...

Page 136: ......

Page 143: ......