The mounting arrangement is designed to ensure integrity of the flameproof enclosure.

The flash chamber block is stainless steel and is surrounded by an insulating mounting

adapter. It houses the heater and a resistance temperature detector (RTD).

The next section houses sample input connections and stem sealing components. There

are two

⅛

-in O.D. tubing ports in this section; one port is for sample input, the other is the

exhaust for sample flow.

The flash chamber components are within the enclosure cavity and surrounded with

insulating covers. At working temperatures, the surfaces of these covers become very hot

to the touch.

The tip of the cylindrical flash chamber is the port where the flashed sample is taken to the

oven system. The port near the outer diameter of the end of the heated flash chamber

block is the input for carrier gas.

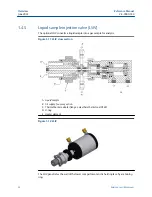

1.4.6

Methanator

After all other components have been separated from the sample, carbon monoxide and

carbon dioxide, which are normally present in quantities too small to be detected by the

gas chromatograph (GC), can be sent through the optional methanator, where the two

gases are combined with hydrogen to make methane in a heat-generated catalytic

reaction.

The methanator is also known as a methanizer or catalytic converter.

1.4.7

Data acquisition

Every second, the controller assembly takes exactly 50 equally spaced data samples (i.e.,

one data sample every 20 milliseconds).

As a part of the data acquisition process, groups of incoming data samples are averaged

together before the result is stored for processing. Non-overlapping groups of 50 samples

are averaged and stored, and thus reduce the effective incoming data rate to 50/10

samples per second. For example, if

N

= 5, then a total of 40/5 or 8 (averaged) data

samples are stored every second.

The value for the variable

N

is determined by the selection of a peak width parameter

(

PW

). The relationship is

N = PW

where

PW

is given in seconds. Allowable values of

N

are 1 to 63; this range corresponds to

PW

values of 2 to 63 seconds.

The variable

N

is known as the integration factor. This term is used because

N

determines

how many points are averaged, or integrated, to form a single value. The integration of

data upon input, before storing, serves two purposes:

•

The statistical noise on the input signal is reduced by the square root of

N

. In the case of

N

= 4, a noise reduction of 2 would be realized.

•

The integration factor controls the bandwidth of the chromatograph signal. It is

necessary to match the bandwidth of the input signal to that of the analysis algorithms

in the controller assembly. This prevents small, short-duration perturbations from

Reference Manual

Overview

2-3-9000-744

June 2022

Rosemount 700XA

25

Summary of Contents for Rosemount 700XA

Page 1: ...Reference Manual 2 3 9000 744 Rev L June 2022 Rosemount 700XA Gas Chromatograph ...

Page 6: ...TxD TD or Sout Transmit data or signal out 6 ...

Page 30: ...Overview Reference Manual June 2022 2 3 9000 744 30 Emerson com Rosemount ...

Page 100: ...Installation and start up Reference Manual June 2022 2 3 9000 744 100 Emerson com Rosemount ...

Page 182: ...Operation and maintenance Reference Manual June 2022 2 3 9000 744 182 Emerson com Rosemount ...

Page 280: ......

Page 281: ......

Page 282: ......

Page 293: ......