MAX II

Bolt Tension Monitor

67

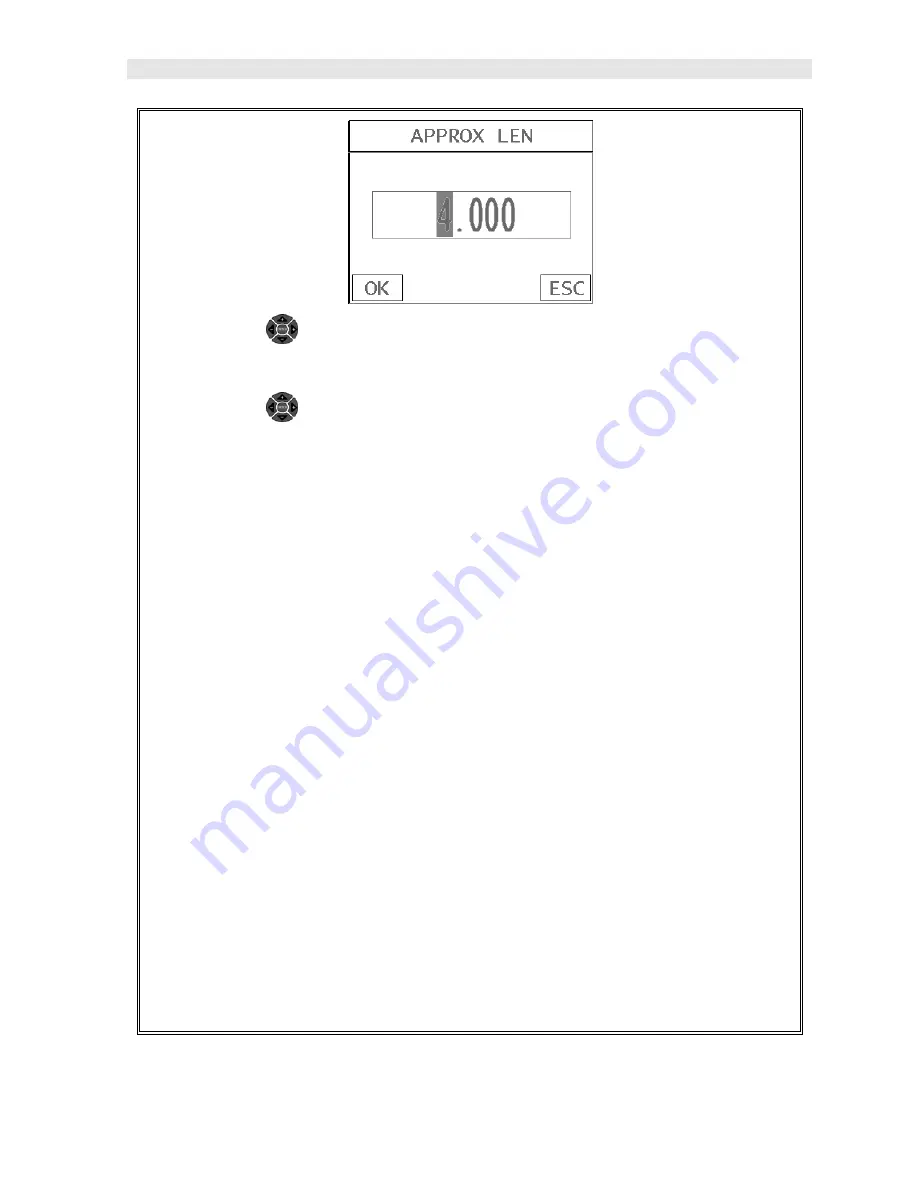

17) Press the

UP

and

DOWN

arrow keys multiple times using the left or

right button wheel to scroll the highlighted value.

18) Press the

LEFT

and

RIGHT

arrow keys multiple times using the left

button wheel to scroll the digit locations.

19) Repeat steps

17 & 18

until the

APPROX LEN

value is correctly displayed.

20) Press the

OK

key to set the

Approximate Length

and return to the menu

screen, or

ESC

to cancel entering the

Approximate Length

.

21) Use the

UP

and

DOWN

arrow keys to scroll through the sub menu items

until

AUTO SET

is highlighted.

Note:

Both the

Approximate Length

and

Auto Set

feature could have also been

set and activated using the

Hot Menu

Items and

Keypad Auto Set

button as

well. However, since we are already in the

Tab Menu

Items, it was just as easy

as returning to the

Hot Menu

Items screen.

22) Apply a drop of couplant to the bolt or transducer, and attach it to one end

of the bolt. Rotate the transducer clockwise and counter clockwise applying

a small amount of pressure to eliminate any excess couplant between the

transducer and bolt surface.

Be sure to always place the transducer in the

same location

.

This will help to eliminate any potential measurement errors

cause by changing the sound path.

Summary of Contents for MAX II

Page 2: ......

Page 7: ......

Page 8: ......

Page 54: ...Dakota Ultrasonics 46 Figure 6 Reflection in a bending bolt ...

Page 215: ......