Dakota Ultrasonics

142

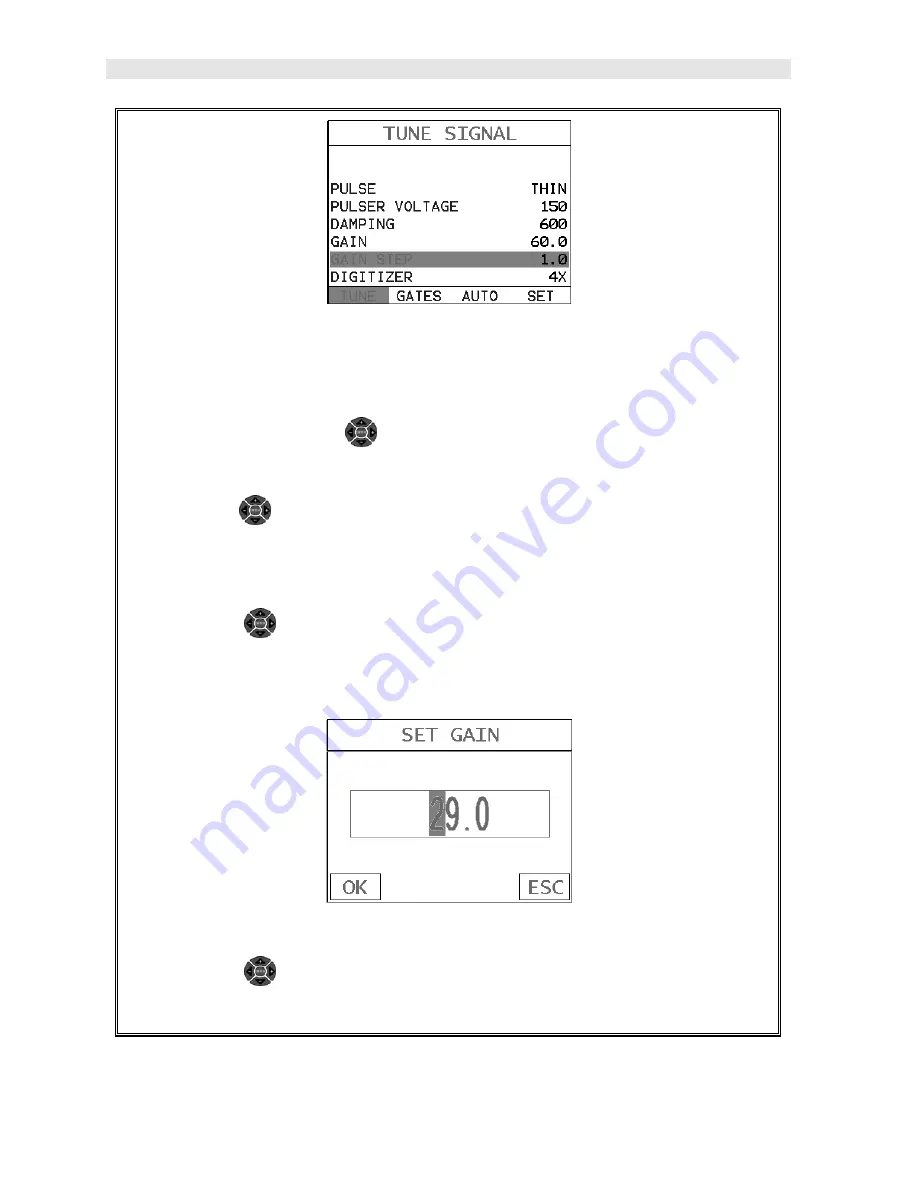

1) Press the

MENU

key once to activate the menu items tab. Press the

MENU

key multiple times to tab right, and the

ESC

key multiple times to tab

left, until the

TUNE

menu is highlighted and displaying the submenu items.

Alternatively, press the

LEFT

and

RIGHT

arrow keys multiple times

using the left button wheel.

2) Press the

UP

and

DOWN

arrow keys multiple times using the left

button wheel to scroll through the sub menu items until

Step Size

is

highlighted.

3) Press the

LEFT

and

RIGHT

arrow keys multiple times using the right

button wheel to scroll the value. When the correct

Step Size

is being

displayed,

proceed to step 8

.

4)

Alternatively

, press the

ENTER

key to display the

Digits Edit Box

.

5) Press the

UP

and

DOWN

arrow keys multiple times using the left or

right button wheel to scroll the highlighted value.

Summary of Contents for MAX II

Page 2: ......

Page 7: ......

Page 8: ......

Page 54: ...Dakota Ultrasonics 46 Figure 6 Reflection in a bending bolt ...

Page 215: ......