BRAKES

5-5

Inspecting Metal Parts

BA DLY D A M A G E D ITEM S, O R TH O SE W H IC H

W O U LD T A K E EX TEN SIV E W O R K O R T IM E TO

R E P A IR , SH O U LD BE R E PL A C E D . In case of doubt,

install new parts. Do not rely on the brake unit being

overhauled at an early or proper interval. New parts will

provide more satisfactory service, even if the brake unit is

allowed to go beyond the desired overhaul period.

Assembly

1. Be careful during the rebuild procedure that no grease

or mineral oil comes in contact with the rubber parts of the

power brake unit.

2. Lubricate power head parts, as outlined below, with

power brake silicone lubricant. This lubricant is provided in

the service repair kit.

Front Housing Group

1. Install a

new

vacuum check valve and a

new

grommet in front housing.

2. Place

new

front housing seal in housing so flat

surface of cup lies against bottom of depression in housing.

Power Piston Group

1. Lubricate the I.D. and O.D. of the "O" ring seal with

silicone lubricant and place on the air valve.

2. Wipe a thin film of silicone lubricant on the large and

small O.D. of the floating control valve.

3. If the floating control valve needs replacement, it will

be necessary to replace the complete air valve-push rod

assembly, since the floating control valve is a com ponent part

of this assembly and cannot be disassembled from the push

rod.

4. Place the air valve end of the air valve-push rod

assembly into the tube of the prim ary power piston. M anually

press the air valve-push rod assembly so that the floating

control valve bottom s on the tube section of the prim ary

power piston. Installer Tool J-23175 can be used to manually

press the floating control valve to its seat.

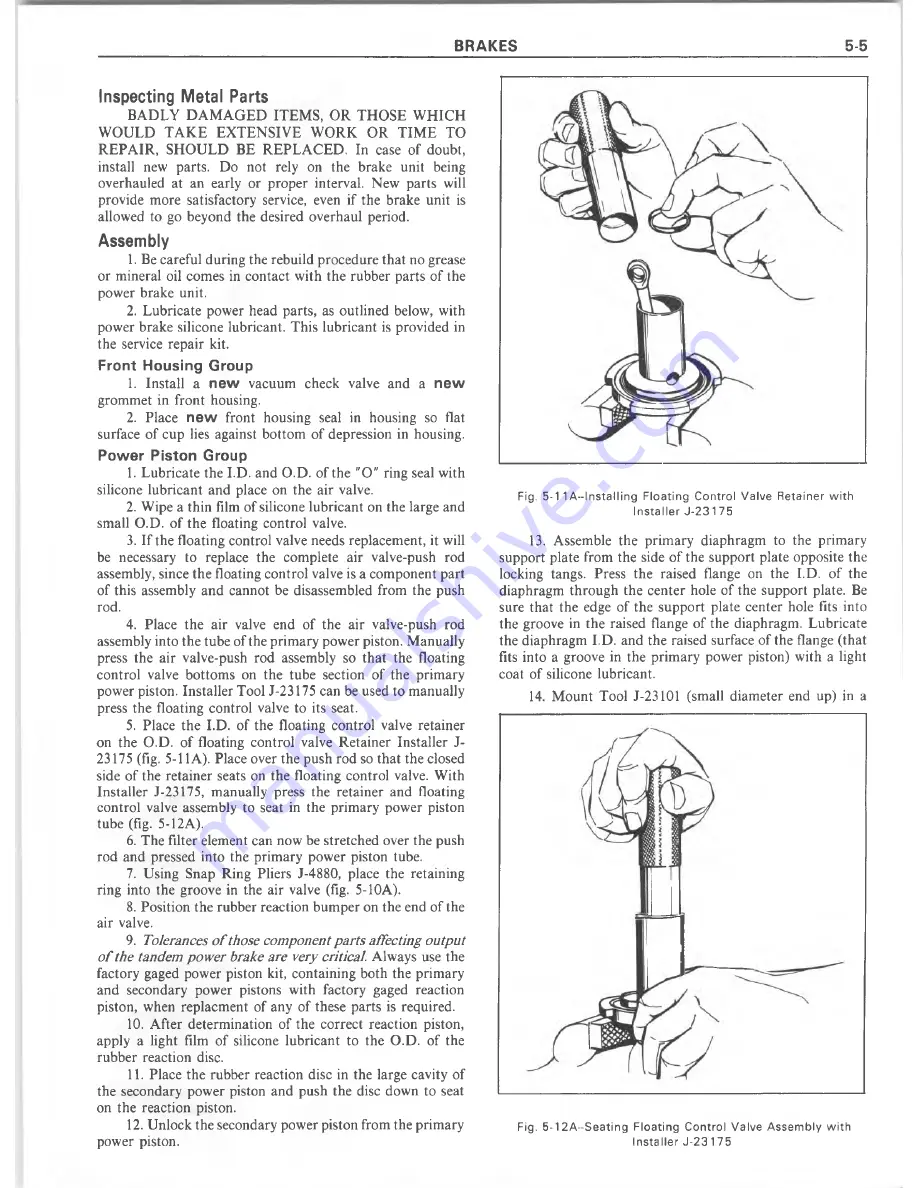

5. Place the I.D. of the floating control valve retainer

on the O.D. of floating control valve R etainer Installer J-

23175 (fig. 5-11 A). Place over the push rod so that the closed

side of the retainer seats on the floating control valve. W ith

Installer J-23175, m anually press the retainer and floating

control valve assembly to seat in the prim ary power piston

tube (fig. 5-12A).

6. The filter element can now be stretched over the push

rod and pressed into the prim ary power piston tube.

7. Using Snap Ring Pliers J-488Q, place the retaining

ring into the groove in the air valve (fig. 5-10A).

8. Position the rubber reaction bum per on the end of the

air valve.

9.

Tolerances o f those component parts affecting output

o f the tandem power brake are very critical.

Always use the

factory gaged power piston kit, containing both the prim ary

and secondary power pistons with factory gaged reaction

piston, when replacment of any of these parts is required.

10. After determ ination of the correct reaction piston,

apply a light film of silicone lubricant to the O.D. of the

rubber reaction disc.

11. Place the rubber reaction disc in the large cavity of

the secondary power piston and push the disc down to seat

on the reaction piston.

12. Unlock the secondary power piston from the prim ary

power piston.

Fig. 5-1 1 A —I nsta llin g F lo a tin g C o n tro l V a lve R e ta in e r w ith

In s ta lle r J -2 3 1 75

13.

Assemble the prim ary diaphragm to the prim ary

support plate from the side of the support plate opposite the

locking tangs. Press the raised flange on the I.D. of the

diaphragm through the center hole of the support plate. Be

sure that the edge of the support plate center hole fits into

the groove in the raised flange of the diaphragm. Lubricate

the diaphragm I.D. and the raised surface of the flange (that

fits into a groove in the prim ary power piston) with a light

coat of silicone lubricant.

14. M ount Tool J-2 3 101 (small diam eter end up) in a

Fig. 5 -1 2 A - S e a tin g F lo a tin g C o n tro l V a lv e A s s e m b ly w ith

In s ta lle r J-2 3 1 75

Summary of Contents for 1977 10 Series

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 42: ......

Page 65: ...STEERING 3B 23 Fig 3B 65 M easure Back and Remark Housing Fig 3B 67 Tighten Lock Nut...

Page 86: ...4B 14 OVERHAUL MANUAL Fig 4B 28 Gear Teeth C ontact Pattern Check...

Page 125: ...REAR AXLE DIFFERENTIAL 4B 53 Fig 18E Gear Teeth Contact Pattern Check...

Page 156: ......

Page 164: ...4C 8 OVERHAUL MANUAL Fig 4C 12 Gear Tooth Pattern Contact Pattern...

Page 166: ......

Page 194: ......

Page 284: ......

Page 320: ......

Page 322: ...400 7A 2 OVERHAUL MANUAL Fig 7A 1C Side Cross Section Typical...

Page 444: ...7B 64 OVERHAUL MANUAL Fig 7B 11S M od el 2 03 Transfer Case Exploded V iew...

Page 458: ......

Page 466: ......

Page 467: ......

Page 468: ......