4B-64

OVERHAUL MANUAL

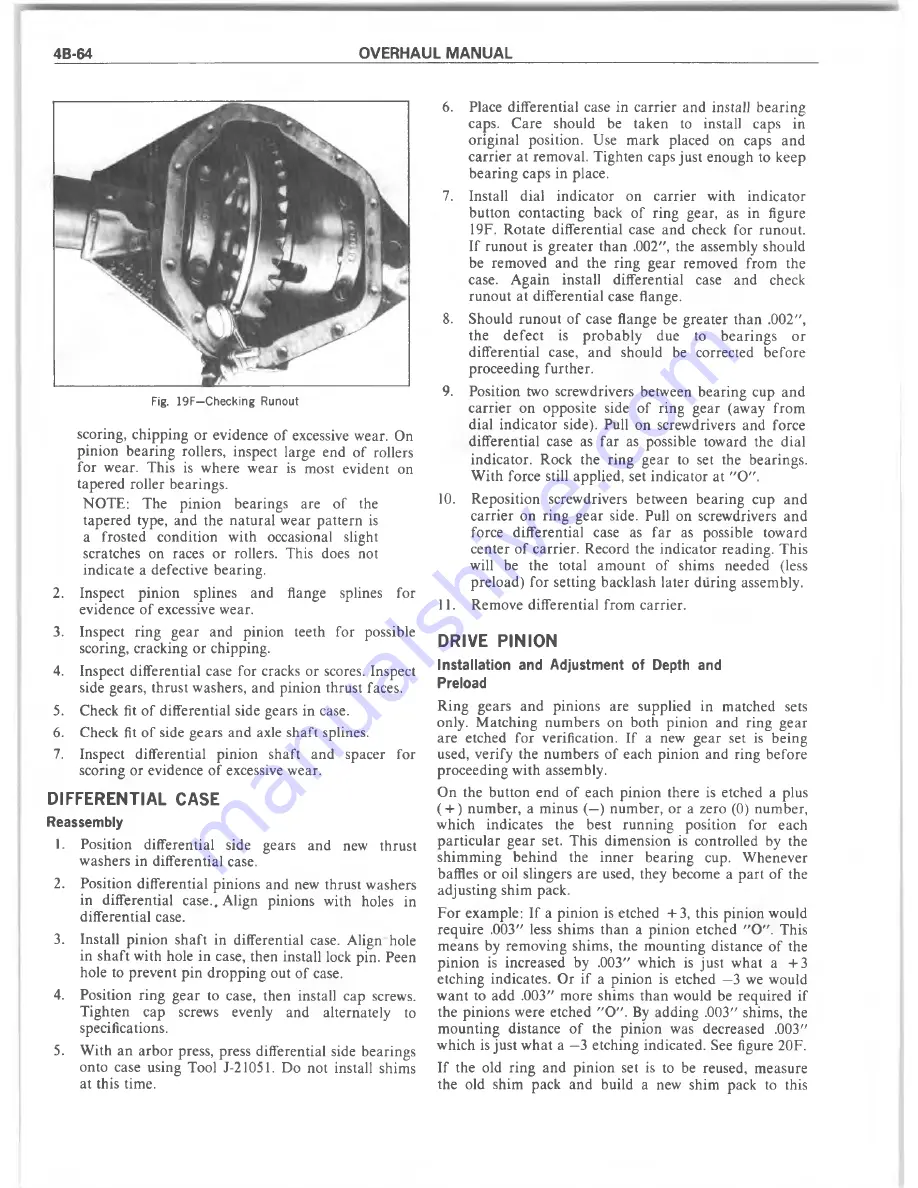

Fig. 19F—Checking Runout

scoring, ch ip p in g o r evidence o f excessive w ear. On

p in io n b earin g rollers, inspect large end o f rollers

fo r w ear. T his is w here w ear is m ost evident on

tap ered roller bearings.

N O T E : T he p in io n b earings are o f the

ta p ered type, and the n a tu ra l w ear p a tte rn is

a frosted co n d itio n w ith occasional slight

scratches on races o r rollers. T his does not

in d icate a defective b earing.

2.

Inspect p in io n splines and flange splines for

evidence o f excessive w ear.

3.

Inspect rin g g e a r and p inion teeth for possible

scoring, cracking or chipping.

4.

Inspect differential case for cracks or scores. Inspect

side gears, th ru st w ashers, and p in io n th ru st faces.

5.

Check fit o f differential side gears in case.

6.

Check fit o f side gears and axle sh aft splines.

7.

Inspect differential p in io n sh aft and spacer for

scoring or evidence o f excessive w ear.

DIFFERENTIAL CASE

Reassembly

1.

P osition differential side gears and new th ru st

w ashers in differential case.

2.

P osition d ifferential p in io n s and new th ru st w ashers

in differential case.. A lign pinions w ith holes in

differential case.

3.

Install p in io n sh a ft in differential case. A lign hole

in sh a ft w ith hole in case, th en install lock pin. Peen

hole to p rev en t p in d ro p p in g out o f case.

4.

Position rin g g e a r to case, then install cap screws.

T ig h ten cap screws evenly and altern ately to

specifications.

5.

W ith a n a rb o r press, press differential side b earings

onto case using Tool J-21051. D o not install shim s

at this tim e.

6.

Place differen tial case in c arrier and install b e arin g

caps. C are should be taken to install caps in

o rig in al position. Use m ark placed on caps and

ca rrie r at rem oval. T ighten caps ju st enough to keep

b e a rin g caps in place.

7.

Install d ial in d ica to r on carrie r w ith in d ic a to r

b u tto n co ntacting back o f ring gear, as in figure

19F. R o tate differential case and check fo r ru n o u t.

If ru n o u t is g re a te r th a n .002", the assem bly should

be rem oved and the rin g g ear rem oved from the

case. A g ain install differential case and check

ru n o u t at differential case flange.

8.

Should ru n o u t o f case flange be g reate r th a n .002",

th e d e fe c t is p ro b a b ly due to

b e a rin g s o r

d ifferential case, and should be corrected b efo re

p ro ceed in g fu rth er.

9.

P osition two screw drivers betw een b earin g cup an d

ca rrie r on opposite side o f rin g gear (aw ay fro m

dial in d ic a to r side). Pull on screw drivers and force

d ifferential case as fa r as possible tow ard the d ial

in d icato r. Rock the rin g g ear to set the bearings.

W ith force still applied, set in d icato r at "O " .

10.

R eposition screw drivers betw een b earin g cup and

c a rrie r on rin g g e a r side. Pull on screw drivers an d

force differen tial case as fa r as possible tow ard

cen ter o f carrier. R ecord the in d icato r reading. T his

will be the total am o u n t o f shim s needed (less

p relo ad ) fo r setting backlash later d u rin g assem bly.

11.

R em ove d ifferential from carrier.

DRIVE PINION

Installation and Adjustment of Depth and

Preload

R ing gears an d p in io n s are supplied in m atched sets

only. M atch in g nu m b ers on both p in io n and ring g ear

are etched fo r verification. If a new g ear set is b eing

used, verify the n u m b ers o f each p in io n and ring b efore

p ro ceed in g w ith assem bly.

O n the b u tto n end o f each p in io n there is etched a plus

( + ) n u m b er, a m inus (—) n u m b er, or a zero (0) n um ber,

w hich indicates the best ru n n in g position for each

p a rtic u la r g ear set. T his d im en sio n is controlled by the

sh im m in g b e h in d the in n e r b earin g cup. W henever

baffles o r oil slingers are used, they becom e a p a rt o f the

ad ju stin g shim pack.

F o r exam ple: If a p in io n is etched + 3, this p in io n w ould

re q u ire .003" less shim s th a n a p in io n etched " O " . T his

m eans by rem oving shim s, the m o u n tin g distance o f the

p in io n is increased by .003" w hich is ju st w hat a + 3

etch in g indicates. O r if a p in io n is etched —3 we w ould

w a n t to add .003" m ore shim s th a n w ould be req u ired if

the p in io n s w ere etched " O " . By ad d in g .003" shim s, the

m o u n tin g distance o f the p in io n was decreased .003"

w hich is ju st w h at a —3 etching indicated. See figure 20F.

If the old rin g an d p in io n set is to be reused, m easure

the old shim pack an d build a new shim pack to this

Summary of Contents for 1977 10 Series

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 42: ......

Page 65: ...STEERING 3B 23 Fig 3B 65 M easure Back and Remark Housing Fig 3B 67 Tighten Lock Nut...

Page 86: ...4B 14 OVERHAUL MANUAL Fig 4B 28 Gear Teeth C ontact Pattern Check...

Page 125: ...REAR AXLE DIFFERENTIAL 4B 53 Fig 18E Gear Teeth Contact Pattern Check...

Page 156: ......

Page 164: ...4C 8 OVERHAUL MANUAL Fig 4C 12 Gear Tooth Pattern Contact Pattern...

Page 166: ......

Page 194: ......

Page 284: ......

Page 320: ......

Page 322: ...400 7A 2 OVERHAUL MANUAL Fig 7A 1C Side Cross Section Typical...

Page 444: ...7B 64 OVERHAUL MANUAL Fig 7B 11S M od el 2 03 Transfer Case Exploded V iew...

Page 458: ......

Page 466: ......

Page 467: ......

Page 468: ......