REAR AXLE DIFFERENTIAL

4B-57

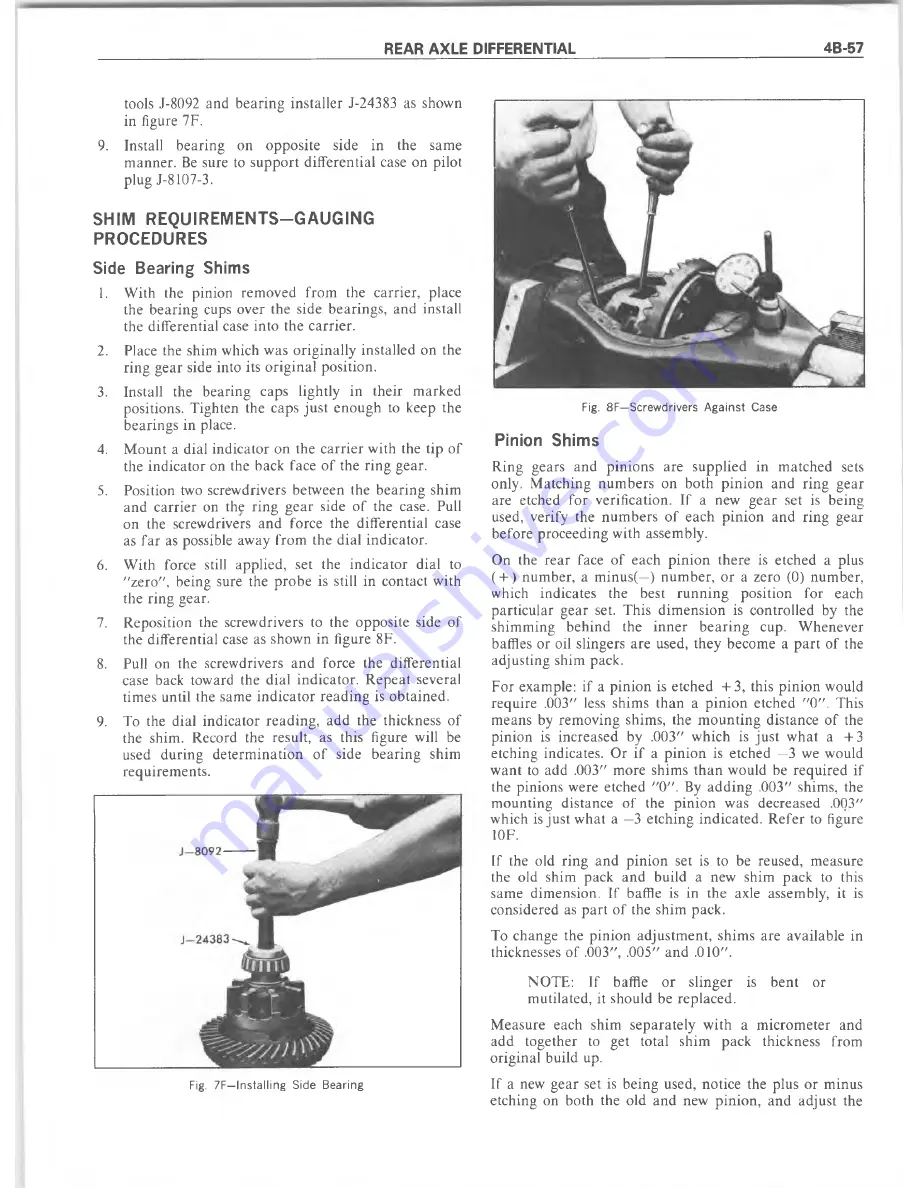

tools J-8092 and b e a rin g in staller J-24383 as shown

in figure 7F.

9.

Install b earin g on o p p o site side in the sam e

m anner. Be sure to su p p o rt differen tial case on pilot

plug J-8107-3.

SHIM REQUIREMENTS—GAUGING

PROCEDURES

Side Bearing Shims

1.

W ith the pinion rem oved from the carrier, place

the b earin g cups over the side bearings, and install

the differential case into the carrie r.

2.

Place the shim w hich w as o rig in a lly installed on the

ring gear side into its o rig in a l position.

3.

Install the b earing caps lightly in th eir m ark ed

positions. T ighten the caps ju s t en o u g h to keep the

bearings in place.

4.

M o u n t a dial in d icato r on the c a rrie r w ith the tip o f

the in d icato r on the back face o f the rin g gear.

5.

Position two screw drivers betw een the b earin g shim

an d carrier on the rin g g e a r side o f the case. Pull

on the screw drivers an d force the d ifferential case

as fa r as possible away fro m the d ial indicator.

6.

W ith force still applied, set the in d icato r dial to

"z e ro " , being sure the p ro b e is still in contact w ith

the rin g gear.

7.

R eposition the screw drivers to the opposite side o f

the differential case as show n in figure 8F.

8.

Pull on the screw drivers an d force the differential

case back tow ard the d ial in d ica to r. R ep eat several

tim es until the sam e in d ic a to r re a d in g is ob tain ed .

9.

To the dial in d icato r re a d in g , add the thickness o f

the shim . R ecord the result, as this figure will be

used d u rin g d ete rm in a tio n o f side b earin g shim

requirem ents.

Fig. 7F—Installing Side Bearing

Fig. 8F—Screwdrivers A g a in st Case

Pinion Shims

R ing gears and p in io n s are supplied in m atched sets

only. M atching n u m b ers on both p in io n an d rin g gear

are etched fo r verification. If a new g ea r set is being

used, verify the n u m b ers o f each p in io n an d ring gear

b efore p roceeding w ith assem bly.

On the re a r face o f each p in io n th ere is etched a plus

( + ) num ber, a m inus(—) n u m b er, o r a zero (0) n um ber,

w hich indicates the best ru n n in g position for each

p a rticu lar gear set. T his d im en sio n is controlled by the

shim m ing b ehind the in n e r b e a rin g cup. W henever

baffles or oil slingers are used, th ey becom e a p a rt o f the

adjusting shim pack.

F or exam ple: if a p in io n is etched + 3 , this p in io n would

req u ire .003" less shim s th a n a p in io n etched " 0 " . T his

m eans by rem oving shim s, the m o u n tin g distance o f the

p in io n is increased by .003" w hich is ju st w h at a + 3

etching indicates. O r if a p in io n is etched —3 we would

w ant to add .003" m ore shim s th a n w ould be req u ired if

the pinions were etched "0 " . By a d d in g .003" shim s, the

m ounting distance o f the p in io n w as d ecreased .003"

w hich is ju st w hat a —3 etching in d icated . R e fe r to figure

10F.

If the old rin g and p in io n set is to be reused, m easure

the old shim pack an d build a new shim pack to this

sam e dim ension. If baffle is in the axle assem bly, it is

considered as p a rt o f the shim pack.

To change the p in io n ad ju stm en t, shim s are available in

thicknesses o f .003", .005" and .010".

N O T E :

If baffle o r slin g er is ben t or

m utilated, it should be replaced.

M easure each shim sep arately w ith a m icro m eter and

add together to get total shim pack thickness from

o rig in al build up.

If a new g ear set is being used, notice the plus or m inus

etching on both the old and new p in io n , an d adjust the

Summary of Contents for 1977 10 Series

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 42: ......

Page 65: ...STEERING 3B 23 Fig 3B 65 M easure Back and Remark Housing Fig 3B 67 Tighten Lock Nut...

Page 86: ...4B 14 OVERHAUL MANUAL Fig 4B 28 Gear Teeth C ontact Pattern Check...

Page 125: ...REAR AXLE DIFFERENTIAL 4B 53 Fig 18E Gear Teeth Contact Pattern Check...

Page 156: ......

Page 164: ...4C 8 OVERHAUL MANUAL Fig 4C 12 Gear Tooth Pattern Contact Pattern...

Page 166: ......

Page 194: ......

Page 284: ......

Page 320: ......

Page 322: ...400 7A 2 OVERHAUL MANUAL Fig 7A 1C Side Cross Section Typical...

Page 444: ...7B 64 OVERHAUL MANUAL Fig 7B 11S M od el 2 03 Transfer Case Exploded V iew...

Page 458: ......

Page 466: ......

Page 467: ......

Page 468: ......