2.2.2 Installation cautions

Item

Description

Antirust treatment

◆

Before installation, please wipe the "rust-proof agent" of the extension end

of the servo motor shaft, and then do the relevant rust-proof treatment.

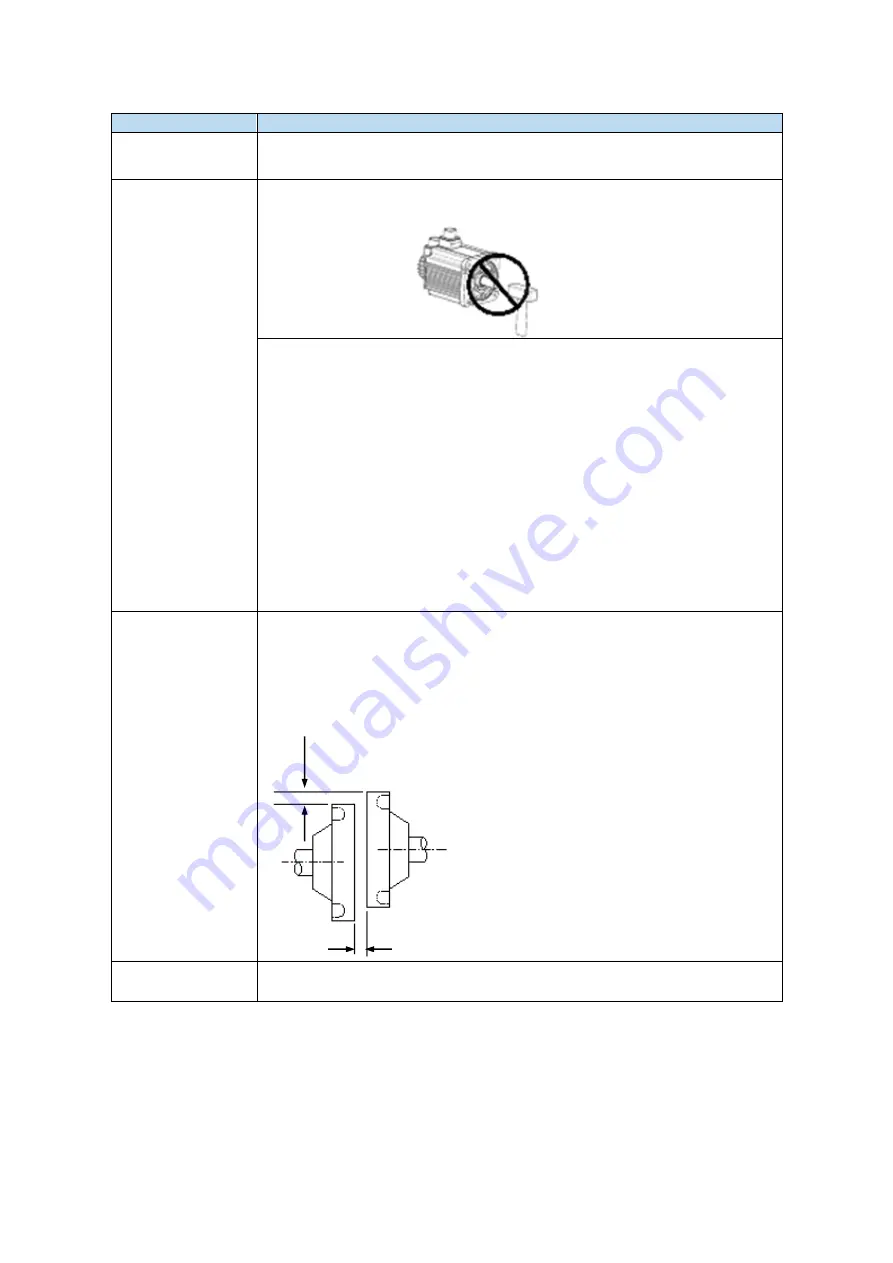

Encoder cautions

◆

It is forbidden to impact the extension end of the shaft during installation,

otherwise the internal encoder will be broken.

◆

When the pulley is installed on the servo motor shaft with keyway, the

screw hole is used at the end of the shaft. In order to install the pulley, the

double-headed nails are inserted into the screw holes of the shaft, the washer is

used on the surface of the coupling end, and the pulley is gradually locked with

the nut.

◆

For the servo motor shaft with keyway, use the screw hole at the end of the

shaft to install. For shaft without keyway, friction coupling or similar methods

are used.

◆

When the pulley is dismantled, the pulley mover is used to prevent the

bearing from being strongly impacted by the load.

◆

To ensure safety, protective covers or similar devices, such as pulleys

installed on shaft, are installed in the rotating area.

Centering

◆

When installing the servo motor, make it conform to the centering accuracy

requirement shown in the picture below. If the centering is inadequate, vibration

will occur, and sometimes the bearing and encoder may be damaged. When

installing the coupling, please do not directly impact the motor shaft, otherwise

the encoder installed on the opposite side of the load shaft will be damaged.

Installation

direction

◆

Servo motor can be installed in horizontal or vertical direction.

The maximum and minimum deviations are

less than 0.03mm (rotated with the coupling)

measured at four locations in a circle.

The maximum and minimum deviations are less than 0.03mm

(rotated with the coupling) measured at four locations in a circle.

Содержание DS5L1 Series

Страница 1: ...DS5L1 series servo driver User manual WUXI XINJE ELECTRIC CO LTD Data No SC5 05 20200929 1 0 ...

Страница 2: ......

Страница 6: ......

Страница 33: ...Voltage DC 30V maximum Current SO1 DC 500mA maximum 400W and below servo can support SO others DC 50mA maximum ...

Страница 100: ...3 Set the auto tuning interface 4 Click ok to start inertia identification ...

Страница 106: ...3 set the auto tuning interface ...

Страница 112: ...with higher rigidity 6 Start auto tune 7 Open the servo enable then click ok ...

Страница 169: ...Appendix 9 Torque speed characteristic curve ...

Страница 170: ......