SECTION 4 - BOOM & PLATFORM

4-2

– JLG Lift –

3121827

4.

Remove hardware securing telescope cylinder #1 to

the fly boom section, then remove pin from fly.

5.

Remove hardware securing telescope cylinder to

the base boom section.

WHEN REMOVING TELESCOPE CYLINDER FROM BOOM SEC-

TIONS. CARE SHOULD BE TAKEN NOT TO LET CYLINDER REST

ON POWERTRACK WHICH COULD CAUSE DAMAGE TO POW-

ERTRACK.

6.

Using a suitable lifting device, remove telescope cyl-

inder from boom sections.

7.

Using a piece of tape, mark the length of hoses and

wires from front of fly boom and bottom of base

boom for reassembly.

8.

Remove hardware securing the front cover on base

boom section.

9.

Loosen jam nuts on front wear pad adjustments and

loosen adjustments.

10.

Remove hardware securing the front wear pads on

base boom section, remove wear pads.

11.

Remove wire clamp on the inside of the fly nose.

12.

Manually push the fly boom section into base boom

section to gain access to the power track attach-

ment bolts on the right side of the base boom sec-

tion.

13.

Remove hardware securing the power track to the

aft end of the fly boom section.

14.

Using a suitable lifting device, remove fly boom from

boom section.

15.

Remove hydraulic lines and electrical cables from

power track.

16.

Remove hardware securing power track to the base

boom section. Remove power track.

Inspection

1.

Inspect boom pivot pin for wear, scoring or other

damage, and for tapering or ovality. Replace pin as

necessary.

2.

Inspect lift and master cylinder pins for wear, scoring

or other damage, and for tapering or ovality. Ensure

pin surfaces are protected prior to installation.

Replace pins as necessary.

3.

Inspect telescope cylinder rod attach pin for wear,

scoring or other damage. Replace pin as necessary.

4.

Inspect inner diameter of boom pivot bushings for

scoring, distortion, wear or other damage. Replace

bushings as necessary.

5.

Inspect wear pads for wear as shown in Section 4.7,

Wear Pads.

6.

Inspect all threaded components for damage such

as stretching, thread deformation, or twisting.

Replace as necessary.

7.

Inspect structural units of boom assembly for bend-

ing, cracking, separation of welds, or other damage.

Replace boom sections as necessary.

Assembly

1.

Install power track to the attach point on the inside

of the base boom section. Secure power track with

hardware.

2.

Install hydraulic lines and electrical cables into the

power track.

3.

Install wear pads to the aft end of the fly section.

4.

Using suitable lifting equipment, slide fly section into

the base section until power track attach point aligns

with holes in side of base section.

5.

Attach the power track to the aft end of fly boom

section. Secure power track with hardware.

Содержание JLG E400AJP

Страница 2: ......

Страница 21: ...SECTION 1 SPECIFICATIONS 3121827 JLG Lift 1 7 Figure 1 2 Operator Maintenance Lubrication Diagram...

Страница 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Страница 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Страница 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 13 Figure 3 4 Frame Mounted Electrical Components Sheet 1 of 2...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 14 JLG Lift 3121827 Figure 3 5 Frame Mounted Electrical Components Sheet 2 of 2...

Страница 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Страница 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Страница 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Страница 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Страница 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Страница 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 58 JLG Lift 3121827 Figure 3 23 Generator System Analyzer Flow Chart...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

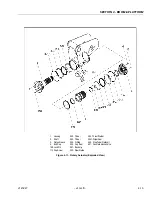

Страница 125: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 9 Figure 4 8 Jib Platform Components and Attaching Hardware...

Страница 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Страница 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Страница 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Страница 179: ...SECTION 5 HYDRAULICS 3121827 JLG Lift 5 25 Figure 5 27 Main Valve Components Prior to S N 62642...

Страница 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Страница 257: ......