34

OPERATING PROCEDURES

:

Data Saving, Loading, and Control

2.3

Data Saving, Loading, and Control

2.3.1

For JOB, PTN, TMP data

{

Contents of JOB data

Traced data, all processing conditions, and layout information are all stored in the JOB data.

{

Contents of PTN data

Traced data, FPD (DBL), size, passive/active, lens material, lens type, frame type, polishing process-

ing, and safety beveling data are all stored in the PTN data. PD and vertical layout data are not stored.

{

Contents of TMP data

When blocking is performed with JOB/PTN# at 0, the data is stored in the TMP folder automatically.

TMP data is used when there is no stored data.

2.3.2

Saving JOB, PTN, and TMP data in the internal memory

{

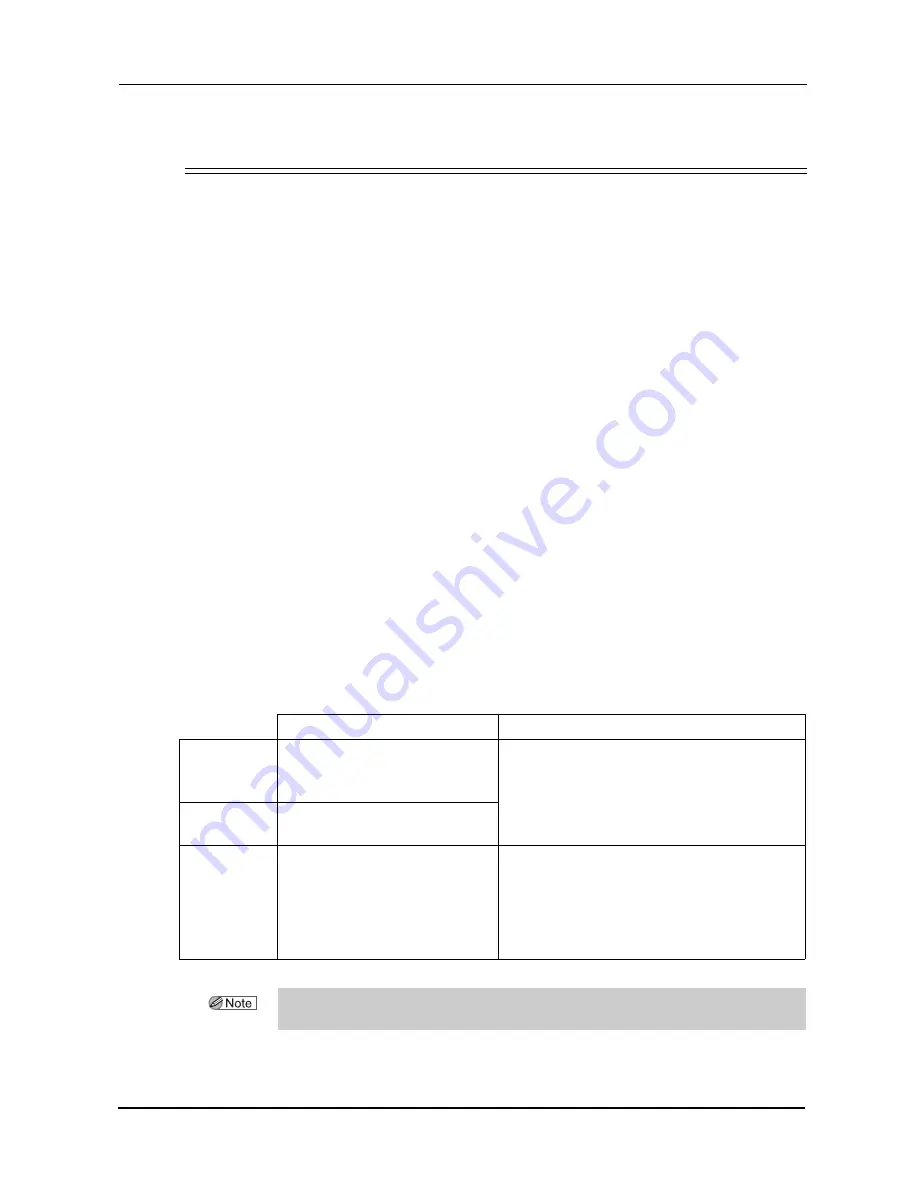

Applying numbers rules

Depending on the method of number application, select among from JOB, PTN, and TMP and save it.

Number entry

Data storage amount

JOB

Alphanumeric characters not

including hyphen (-) (16 digits

maximum)

When saving in the internal memory, a maximum of

500 folders, 500 data items per folder, and the total of

30,000 or less* data items can be saved.

* The maximum number of data to be saved depends

on the size of the data.

PTN

Alphanumeric characters including

hyphen (-) (16 digits maximum)

TMP

If JOB/PTN# is 0, the number is set

as file number (date, time)

automatically.

The number of data to be saved in the TMP folder is

30 at the maximum.

If the number of data items exceeds 30, the data

overwrites oldest data according to date.

This file number (date, time) is not related with the

parameter setting (date format).

• As the amount of data increases, the time required for saving or loading also increases, so

delete or move any unnecessary data.