19

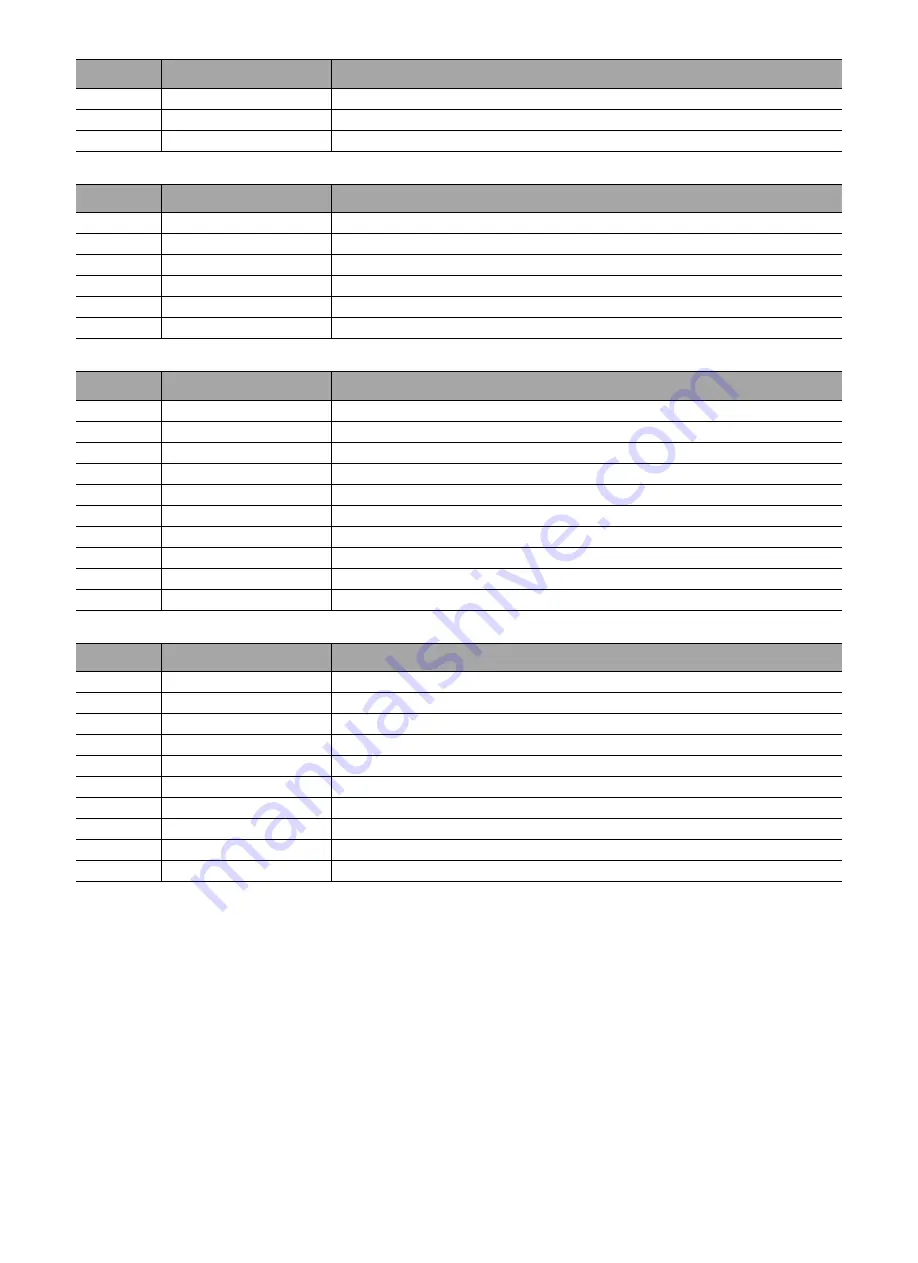

J7 to Motor Connector

J8 to JTAG Connector (micro programming)

J9 Connector to Plunger Driver

24

+5V

+5V power supply

25

CMD_FAIL

LED command failure

26

GND

Ground

Pin n°

Signal

Description

1

MOTP_OUT1B

Output B of the coil 1

2

MOTP_OUT1A

Output A of the coil 1

3

MOTP_OUT2A

Output A of the coil 2

4

MOTP_OUT2B

Output B of the coil 2

5

GND

Ground

6

GND

Ground

Pin n°

Signal

Description

1

GND

Ground

2

+3V3

+3.3V power supply

3

TRST/

Test reset

4

TDO

Test data output

5

GND

Ground

6

TDI

Test data input

7

MR/

Manual reset

8

TMS

Test mode select

9

TCK

Test clock

10

GND

Ground

Pin n°

Signal

Description

1

GND

Ground

2

PLGH_OPTO/

Analog output signal of the piston photomicrosensor

3

FORCE -

Negative input of the force sensor

4

FORCE +

Positive input of the force sensor

5

+3V3

3V3 power supply of force sensor

6

DSG_OPTO/

Analog output signal of the release photomicrosensor

7

PLGHDSG_CD_OPTO

Power supply signal of the photomicrosensors

8

DSG_SW_ON/

Analog output signal of the release switch

9

DSG_SW_OFF/

Analog output signal of the release switch

10

GND

Ground

Pin n°

Signal

Description

Summary of Contents for Agilia SP

Page 139: ...139 17 Spare Parts Catalog Refer to the spare parts catalog of the relevant pump ...

Page 143: ...143 VTBI Volume to Be Infused W Watts Term Description ...

Page 147: ...Local Contacts for Servicing Write your contacts here ...

Page 148: ...11378 2_tm_agilia_sp_eng ...

Page 305: ...Local Contacts for Servicing Write your contacts here ...