92

SERVICE MANUAL FOR SGR19 & SGR17

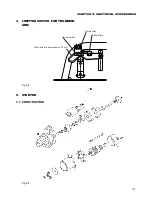

4.2. REASSEMBLY

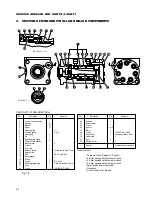

Inspect all disassembled parts for contact sur-

faces for flaws and burr. The parts which have

such defects should be replaced with new ones

because such defects will cause oil leaks. All

metal parts should be washed in fresh solvent

and dried by blowing. Never wipe them with

cloth or paper because paper scrap or lint may

stick on them, which also may cause troubles.

Never try smoothing them with a file or coarse

sand paper.

Note: Principally we recommend the use of new

O-rings and seals when reassembling the mini-

orbit roll. They should be coated with a small

amount of fresh grease ahead of time.

Reassembly of relief valve (only when a relief

valve is installed)

When reassembling a mini-orbit roll without a

relief valve, start reassembling at step 5.

(1) Hold the spring guide of poppet (17) with tweez-

ers and insert it through the flange of the hous-

ing as shown in section A-A. Make sure that the

poppet is installed properly.

(2) Insert spring (18) and damper collar (32).

(3) Fit O-ring (19) onto relief adjusting plug (20)

and screw in the plug into housing (2) as shown

in section A – A.

(4) Adjust the pre-set pressure of the steering relief

valve after the mini-orbit roll has been reassem-

bled. When the valve is required to be set to the

pre-disassembled pressure, re-set it to the same

depth as it is before disassembly at disassem-

bling step 18. The pressure shift by one turn of

relief adjusting plus is about 15 kgf·cm

2

.

(5) Install ball (16) and retainer pin (15) in this or-

der into the tapped hole in housing (2) as shown

in section A – A. Then set retainer screw (13)

and tighten it to 1.3 kgf·m with a 3.0 m hexago-

nal set screw wrench.

(6) Insert dust seal (13) from the end of housing (2)

with the flat surface turned downward.

(7) Installation of oil seal (12)

a. Install one bearing race (11) and sleeve (3) into

the bore of housing (2).

b. The space formed by the installed bearing race

and the housing provides a groove for oil seal

(12).

c. Push the sleeve inward manually from the G-

rotor side so that the centres of the sleeve and

the bearing race is almost aligned.

d. While keeping the sleeve and bearing race

aligned in centre, set oil seal (12) in the groove

from the flange side of the housing.

e. After having installed the oil seal, remove the

pre-installed sleeve and bearing race.

(8) Place the housing with the flange turned down-

ward and install bearing race (11), thrust needle

bearing (10), and bearing race (11) in this order.

(9) Insert sleeve (3) onto spool (4) and align the

spring installation openings in the spool and

sleeve. Then first insert two flat springs (7) and

next insert all the centring springs to be installed

into the openings at the same time while two

halves of the centring springs are set as shown

in the drawing: the two halves should be faced

in opposite directions.

(10) After inserting the springs, fit spring retaining

ring (9) over the springs. Apply grease to the

clearance between the sleeve and retaining ring.

Insert pin (8) through the sleeve and spool. With

this operation, the spool/sleeve assembly is com-

pleted.

(11) Install the spool/sleeve assembly from the G-ro-

tor side.

Note: When inserting the spool/sleeve assembly,

take care not to allow it to slant and bite the

housing. Insert it with the pin kept level while

turning the assembly a little in both directions

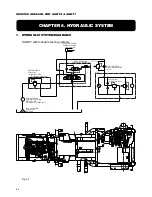

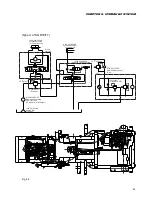

Содержание SCM49

Страница 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Страница 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Страница 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...

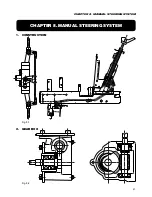

Страница 97: ...97 CHAPTER 8 MANUAL STEERING SYSTEM CHAPTER 8 MANUAL STEERING SYSTEM 1 CONSTRUCTION Fig 8 1 2 GEAR BOX Fig 8 2 ...