106

SERVICE MANUAL FOR SGR19 & SGR17

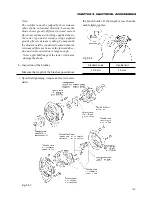

Fig. 9-17

6) Inspection of the brushes

• Measure brush length in the middle.

Standard value

Usable limit

15.0 mm

10.0 mm

8) Inspection of the brush holder

• Inspect for insulation across positive (+) side and

negative (-) side of the brush holder. If there is

no continuity, the brush holder is normal.

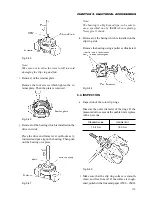

Fig. 9-18

• Correct the contact surfaces of the brushes on

the sandpaper wrapped around the commutator.

7) Inspection of brush spring tension

• Measure spring tension with a spring balance and

read the balance at the moment when the spring

is about to leave the brush.

Standard value

Usable limit

1785 - 2415 gr

1200 gr

Fig. 9-19

Fig. 9-20

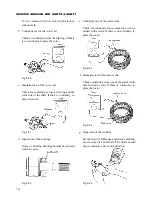

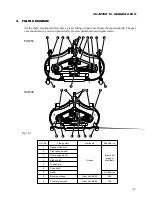

9) Inspection of the clutch

• Inspect the gear for wear and damage.

• Make sure that the gear locks when turned in

diving direction and turns smoothly in the re-

verse direction.

Fig. 9-21

• There should be no hitching when the bearing is

turned manually by applying some force to it

with fingers.

• It should not make abnormal noises when turned

abruptly.

Fig. 9-22

11) Replacement of the bearing

• Remove the bearing or install it as illustrated.

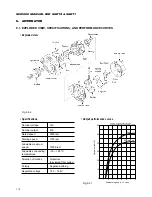

Содержание SCM49

Страница 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Страница 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Страница 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...

Страница 97: ...97 CHAPTER 8 MANUAL STEERING SYSTEM CHAPTER 8 MANUAL STEERING SYSTEM 1 CONSTRUCTION Fig 8 1 2 GEAR BOX Fig 8 2 ...