25

CHAPTER 3. ENGINE

5. COMPRESSION AND UNLOADED IDLING

SPEEDS

5.1. Inspection of compression

1) Remove the injection pipes.

2) Remove a injection nozzle.

Note:

Cap the injection nozzles, injection pump, and

injection pipes to avoid dust.

3) Install a compression gauge using an adaptor.

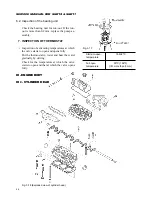

Fig. 3-14

4) Activate the starter and measure the compres-

sion.

kg/cm

2

at 300 rpm

Standard

Limit

Difference

between cylinders

30

26

3

Note:

• Use a fully charged battery.

• Be sure to remove the fuel pipes in advance to

avoid fuel injection.

• Remove only the nozzle for the cylinder whose

compression is to be measured. Other nozzles

should be left installed.

Caution:

When cranking the engine, take care not to

touch rotating parts.

5.2. Inspection and adjustment of the idling

speeds

1) Check for idling speeds.

Specified value

1250 rpm

2) When the measured value deviates from the

specified value, correct with an adjusting

bolt.

Fig. 3-15

6. INSPECTION OF WATER PUMP

6.1. Inspection of the pump and pulley

Check the pump for noise or hitching by turning

the water pump pulley, applying load vertically

to the pump axis.

When noise or hitching occurs, replace the pump

assembly.

Fig. 3-16

Содержание SCM49

Страница 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Страница 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Страница 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...

Страница 97: ...97 CHAPTER 8 MANUAL STEERING SYSTEM CHAPTER 8 MANUAL STEERING SYSTEM 1 CONSTRUCTION Fig 8 1 2 GEAR BOX Fig 8 2 ...