46

SERVICE MANUAL FOR SGR19 & SGR17

Fig. 3-89

• Install the other snap ring securely in the groove.

Fig. 3-91

• Install the rings with their gaps 120

°

apart from

each other as shown in the figure.

Fig. 3-90

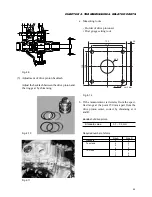

(2) Installation of piston rings

• Install the rings using a piston ring expander with

their “T” marks turned upwards. But the oil rings

have no markings, so they can be installed with

either side up.

• The gaps of the ring and ring expander of the oil

ring should be set apart 180

°

from each other.

Note:

As No.1 and No.2 compression rings have dif-

ferent cross sections, take care not to install them

in wrong order.

No. 2

compression

ring

No. 1

compression

ring

Expander

joint

Oil ring

27

°

Front

Fig. 3-92

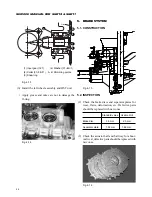

6.

INSTALLATION OF CRANKSHAFT

(1) Install the upper bearings, which have oil grooves

or oil holes, in the cylinder block.

Note:

Bearings and bearing fitting surfaces on the cyl-

inder block should be free from any foreign mat-

ter.

The projection of each bearing should be se-

curely seated in its notch in the cylinder block.

FRONT

1st

2nd

Oil

Chrome-plated

Chrome-plated

Coil expanders

Содержание SCM49

Страница 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Страница 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Страница 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...

Страница 97: ...97 CHAPTER 8 MANUAL STEERING SYSTEM CHAPTER 8 MANUAL STEERING SYSTEM 1 CONSTRUCTION Fig 8 1 2 GEAR BOX Fig 8 2 ...