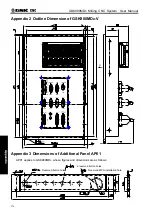

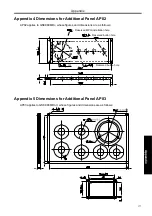

Appendix

387

Appendix

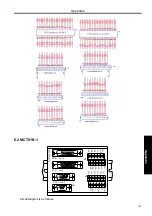

7.2 Setting of Spindle Electronic Gear Ratio

Calculation formula of CNC:

D

M

Z

Z

CMD

CMR

×

=

α

δ

CMR

CMD

Z

Z

D

M

×

×

=

δ

α

CMR: Multiplier coefficient of spindle command

CMD: Frequency division coefficient of spindle command

α

: Pulse volume, motor rotation angle for a pulse

δ

: Min. input command unit of CNC (0.001°, 0.01° or 0.0001°), this value corresponds to the travel

amount of a revolution of the spindle (related parameters 5216). When 5216 is set to 1000,

δ

=360/1000=0.360

°

ZM: Gear teeth of lead screw

ZD: Gear teeth of motor

Calculation formula of spindle servo drive unit:

Parameter 12, 13 of drive unit correspond to the pulse frequency division numerator of position

command respectively. The calculation formulas for pulse frequency division denominator of position

command and gear ratio of drive unit are as follows:

C

N

G

P

×

×

=

×

4

And:

CMR

CMD

Z

Z

C

C

N

P

C

N

G

D

M

×

×

×

×

=

×

×

×

=

×

×

=

δ

α

360

4

360

4

4

P: Correspondence between required pulse amounts for motor rotates 360 degrees and CNC end:

α

/

360

=

P

G: Electronic gear ratio of drive unit, G= position command pulse frequency division numerator/

position command pulse frequency division denominator

N: Set motor rev number to 1

C: Wire number of feedback encoder

In order to enhance the machining accuracy, the gear ratio of spindle servo drive is usually set to 1:1,

namely, G=1 in the above formula, and the evolving process is as follows:

1

360

4

=

×

×

×

×

CMR

CMD

Z

Z

C

D

M

δ

D

M

Z

Z

C

CMD

CMR

×

×

×

=

δ

360

4

In order to match with DAP03, C=1024, spindle connects to the motor, Z

M

/Z

D

=1, and it is suggested

that the data parameter 5216 of CNC is set to 1000 (Now the incremental system of the 5

th

axis is 0.001°)

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

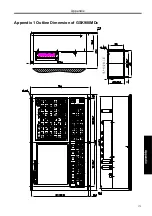

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...