Chapter 6 Screw-Pitch Compensation

369

Ⅲ

Inst

allation

②

Data parameter

№

3620

(

screw-pitch error origin

)

=60

,

№

03624

(

compensation interval

)

=10.000

Parameter

№

3621

(

min. position number of each axis for pitch error compensation

)

=0

,

parameter

№

3622

(

max. position number of each axis for pitch error compensation

)

=199

When the screw-pitch error origin is set to 60: For the positive moving, the compensation value for the

1

st

section is set by the position

№

0061 in the compensation table. The compensation value for the 2

nd

section is set by the position

№

0062 in the compensation table. The compensation value for the Nth is set

by position

№

0060+N in the compensation table.

For the negative moving, the 1

st

section error compensation is set by position

№

0060 in the

compensation table, the 2

nd

section by position

№

059. The Nth section error compensation is set by

position

№

0060-N in the compensation table.

By taking the machine zero as the reference point, the screw-pitch error origin moves from the positive

coordinate system of machine zero to compensate the corresponding position No.0061 in the

compensation table, and from the negative coordinate system to compensate the position No.0060.

Therefore the screw-pitch compensation can be done when moving in the positive or the negative

coordinate system of machine zero.

The position No.0060 in the screw-pitch error compensation parameters corresponds to the reference

point (60), compensation point 61 to a point positive10.000 moving from origin. So there is a compensation

point every 10.000 distance. The 127th offset point is the compensation at po670.000. While the

compensation point 59 corresponds to a point negative 10.000 moving from reference point. Also there is a

compensation point every 10.000 .The offset point 0 is the compensation value at -600.000 position.

Therefore, at compensation point N, set a compensation value when moving from (N-61) × (compensation

interval) to (N-60) × (compensation interval).

Above is the example of following compensation interval errors

Offset interval

Offset value

0

~

10.000

+4

-10.000

~

0

+6

-20.000

~

-10.000

-7

-30.000

~

-20.000

-7

Machine

coordinat

e system

Offset

parameter

No.

Offset

value

Drive unit

current

command pulses

before offsetting

Drive unit current

command pulses after

offsetting

-30.000 058

-7

-30000

-29992

-20.000 059

-7

-20000

-19999

-10.000 060

+6

-10000

-10006

Reference

point 0

0

0

10.000 061

+4

10000

10004

…… 062

…

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

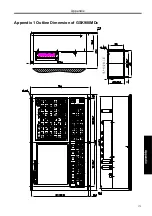

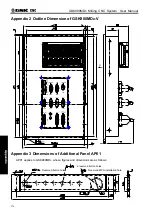

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...