GSK980MDc Milling CNC System User Manual

170

I Programming

same points” and “the last two same points”

z

The alarm and corresponding explanation of ‘Circular arc data error in cutter compensation C’

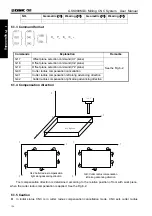

(a) The example of this alarm may occur in a circle

Program example

:

N0 G90 G00 X-50 Y-50 Z50

N1 G01 G42 X0 Y0 D1 F800

N2 G02 I50

N3 G91 G01 X-50 Y-50

Programmed path

Tool center path

r

G42

N1

N2

N3

P2

P1

The transit point between straight line N1 and circular arc N2 is P1, the transit point between circular

N2 and straight line N3 is P2, and the compensation radius is r, in this case, the circular after tool

compensation is more than 360

°.

Programmed path

Tool center path

The path after N9 block is inserted

r

r

G42

N1

N2

N3

P2

P1

The path after N9 block is not inserted

After a block (N9 G91 G0 X0 Y0) (without moving) is inserted between N1 and N2 in the

above-mentioned program, the “circular data error in cutter compensation C” may alarm.

Because the point after N9 inserted which is equal to the one of N1, namely, they are regarded as “two

same points”. The transit point P1 is performed treating the “two same points”, the position of P1 is

obviously differ from the above one which does not insert the N9 block. So the cut circular arc path by this

transit point is absolutely differing from the path to be machined, so the alarm is then generated: “circular

arc data error in cutter compensation C”

(b) The example for a non-circle may occur:

Programmed path

Tool center path

r

N2

N0

N1

P1

P2

Program example: N0 G90 G00 X-50 Y-50 Z50

N1 G01 G41 X0 Y0 D1 F800

N2

G02

X50

R25

The P1 and P2 are the transit point of tool compensation as the left figure shown, wherein the “r” is

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...