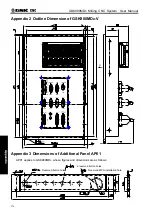

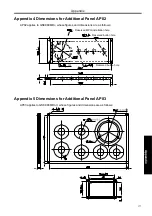

Appendix

389

Appendix

5216

The travel amount of a revolution of

the spindle

Set the value according to the

wire number of feedback

encoder of spindle servo drive

1000(1u),10000

(0.1u)

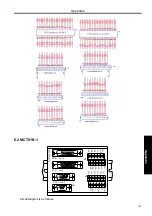

Adjustments of the spindle servo drive (take DAP03 for example) are as follows:

Data

parameter

Significance Adjustment

explanation

Recommended

range

79

The second

proportional gain of

speed ring

The bigger the value is, the higher the rigidity is.

If the rigidity is too big, vibration will occur at the

start and the end. The smaller the value is, the

slower the response will be.

1500~1800

80

The second integral

coefficient of the

speed ring

The bigger the value is, the faster the response

will be. When the value is too big, vibration will

occur. When the value is too small, the response

will be slow and steady state error cannot be

reduced.

5

Appendix 8 Alarm Message

Alarm type: 0-CNC error; 1-CNC warning; 2-PLC error; 3-PLC warning.

Clearing ways: 0-press RESET key to clear; 1-press CANCEL key to clear;

2-press RESET key or CANCEL key to clear; 3-press RESET key and CANCEL key at the

same time to clear; 4-only power-on reset can clear.

Alarm

No.,

TYPE

CLR

WAY

Alarm Message

000,0 0

Emergency

stop!

001,0

0

Part program doesn’t exist or is failed to be opened

002,0

0

The G code is illegal.

003,0

0

Total characters of one command is out of range(2~11characters are allowed)

004,0

0

Tooth pitch vale is overflow.

006,0

0

The format of block is wrong, or the value of block is overflow.

008,0

0

The centre of a circle that defined with I, J, K does not suit coordinates.

010,0

0

One command is commanded repeatedly in the same block

011,0

0

Too many commands are in one line, it cannot exceed 100

012,0

0

The value of the command is out of range

013,0

0

Illegal S value has been commanded when not in analog spindle

014,0

0

After G codes of 00 group and 01 group have been commanded, G codes of 00

group can't be commanded again in the same block.

015,0

0

M code has been commanded when not in analog spindle

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

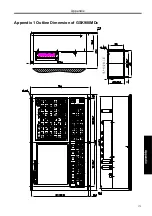

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...