Chapter 5 Macro Program

143

I Programming

Note 4: When feedrate override is disabled, an override of 100% is always applied regardless of the setting of the

feedrate override.

Note 5: When exact stop check is disabled, no exact stop check is made even in blocks including those which do not

perform cutting.

z

Number of machined parts

The number of machined parts can be read and written.

Variable No.

Function

#3901

Number of machined parts

z

Modal information

Modal information specified in blocks up to the immediately preceding block can be read.

Variable No.

Function

#4001

Group 1

(

G00, G01, G02, G03, G73, G74, G80, G81, G82, G83,

G84, G85, G86, G88, G89, G110, G111, G112, G113, G114, G115,

G134, G135, G136, G137, G138, G139

)

#4002

Group 2

(

G17, G18, G19

)

#4003

Group 3

(

G90, G91

)

#4005

Group 5

(

G94, G95

)

#4006

Group 6

(

G20, G21

)

#4007

Group 7

(

G40, G41, G42

)

#4008

Group 8

(

G43, G44, G49

)

#4010

Group 10

(

G98, G99

)

#4014

Group 14

(

G54, G55, G56, G57, G58, G59

)

#4107 D

code

#4109 F

code

#4111 H

code

#4113 M

code

#4114 Block

sequence

number

#4115 Program

name

#4119 S

code

#4120 T

code

z

Current position

Position information can be read.

Variable No.

Function

Read during

movement

#5001~#5005

Workpiece coordinate system block end point

(tool compensation value not included)

Enabled

#5021~#5025

Machine coordinate system current position( tool

compensation value included)

Disabled

#5041~#5045

Workpiece coordinate system current position

(tool compensation value included)

Disabled

#5061~#5065

Workpiece coordinate system skip signal position

( tool compensation value included)

Enabled

#5081~#5085

Tool length compensation value

Disabled

Note 1: The first digit (from 1 to 5) represents an axis number.

Note 2: The tool length compensation value currently used for execution rather than the immediately preceding tool

compensation value is held in variables #5081~#5085.

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

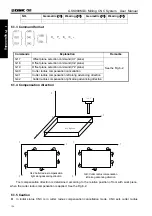

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...