Chapter 6 Cutter Compensation

155

I Programming

CHAPTER 6 CUTTER COMPENSATION

6.1 Application for Cutter Radius Compensation

6.1.1 Brief

Generally, the parts machining process is programmed according to parts drawing in one point on a

tool. As for the tool used actually, because of the processing or other requirement, the tool is not an ideal

point, but an arc only. The position offset exists between actual cutting point and ideal point when the

cutting feed is performed. It may cause over cut or undercut, so the part accuracy will be affected. So, the

cutter radius compensation can be used to improve the part accuracy in machining.

The path of part figure can be shifted by a cutter radius, which this method is called B type tool

compensation; this is a simply method but the movement path of next block can be processed only after a

block is performed, so the phenomenon as over cutting will be generated at the intersection point of two

blocks.

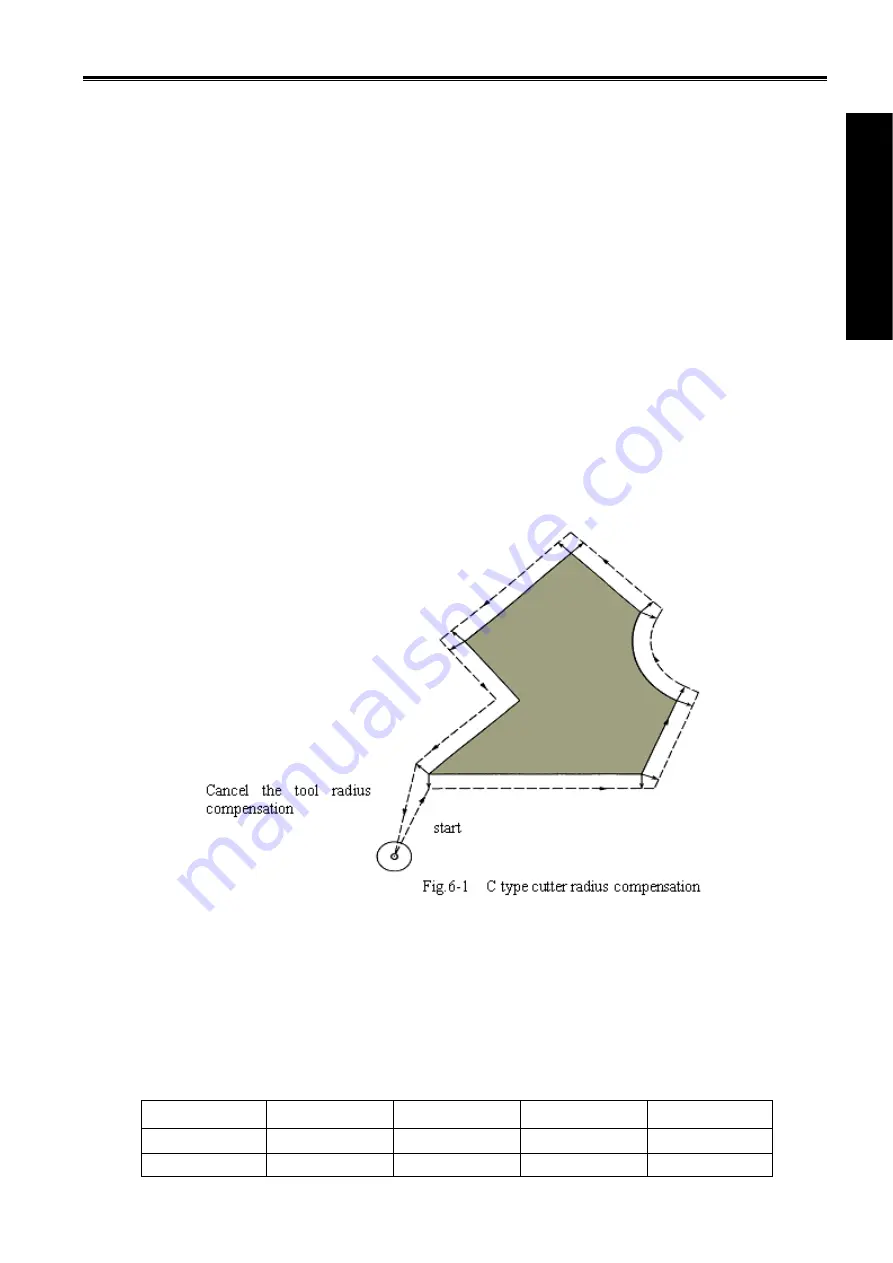

In order to settle the above issues and eliminate the error, the Tool compensation C should be setup.

When a block is read in, the tool compensation C is not performed immediately but the next block is read in

again. Corresponding movement path is calculated according to the point of intersection of two blocks

(conjunction vector). The tool compensation C performs more accurate compensation in figure because two

blocks are read for processing in advance. See the Fig. 6-1

6.1.2 Compensation value setting

The radius value of each tool should be set before tool compensation C is applied. Tool radius

compensation value is set in the OFFSET page (table 6-1), this page contains tool geometric radius and

tool radius wear. There into, D is the tool compensation value, when the bit 1 of bit parameter No.002 is 1,

the D is compensation value input by diameter. If the bit 1 of bit parameter No.002 is 0, the D is

compensation value input by radius. The following explanations are all indicated in radius compensation

value if not especially pointed out.

Table 6-1 Display page for CNC cutter radius compensation value

NO.

Geometric

(

H

)

Wearing

(

H

)

Geometric

(

D

)

Wearing

(

D

)

001 20.020 0.030 5.000 0.020

002 10.020 0.123 0.500 0.030

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...