GSK980MDc Milling CNC System User Manual

168

I Programming

If the canned cycle command is specified in compensation mode, the compensation will be temporarily

cancelled in the canned cycle operation 1. The compensation mode is automatically restored after the

canned cycle is terminated.

6.2.7 Exceptional case

z

When the inner corner machining is less than tool radius

When the inner corner machining is less than tool radius, the inner offset of a tool will cause over cut.

The tool stops and alarm occurs after moving at the beginning or at the corner in previous block. But if the

switch of “Single block” is ON, the tool will be stopped at the end of the previous block.

z

When a groove less than the tool diameter is machined

When the tool center moves opposite to the direction of programmed path, the over cutting will be

generated by the cutter radius compensation. Tool stops and alarm appears after moving at the beginning

of previous block or at the corner.

z

When a step less than the tool radius is machined

When a program contains a step which is an arc and less than tool radius, tool center path may form a

opposite movement direction to the programmed path. So the first vector is ignored and it moves to the end

of the second vector along a straight line. The program will be stopped for Single block mode, the cycle

continues if it is not single block mode. The compensation will be executed correctly and no alarm will be

generated if the step is a straight line. (But the uncut part is reserved.)

z

When the sub-program is contained in G code

CNC should be in compensation cancellation mode before calling the sub-program (namely, before the

G98 is performed). Offset can be applied after entering the sub-program, but the compensation cancellation

Содержание 980MDc

Страница 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Страница 20: ...1 I Programming Programming Ⅰ ...

Страница 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Страница 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Страница 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Страница 192: ...173 Ⅱ Operation Ⅱ Operation ...

Страница 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Страница 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Страница 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Страница 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Страница 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Страница 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Страница 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Страница 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Страница 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Страница 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Страница 320: ...301 Ⅲ Installation Ⅲ Installation ...

Страница 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Страница 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Страница 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Страница 392: ...Appendix 373 Appendix Appendix ...

Страница 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

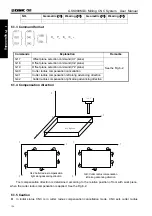

Страница 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...