Inspection and Maintenance — GEK 107048

Hot Gas Path Inspection — Reassembly Procedures

HGP-R-12

CAUTION

Do not stake the forward and aft seals at the horizontal

joint.

3. Ensure that the forward seals are bottomed out and that the ends of the aft seals are in contact with

the forward seals.

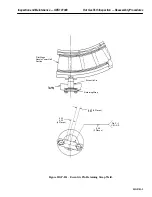

4. Assemble the axial seal strip with the notch facing out. Then assemble the radial seal strip with

the notch facing in. Appropriately stake both seals. See Figures HGP-R.3 and HGP-R.4.

5. Lift the nozzle and diaphragm segment onto its hook fit and slide it along to its proper position.

Install nozzle segments from each horizontal joint to the bottom center line of the casing. Each

nozzle segment and diaphragm weighs approximately 35 pounds.

Note:

Nozzle segment radial retaining pins should be installed after each seg-

ment is moved into position.

6. Apply a light coat of anti-seize compound to all radial retaining pins.

7. Install the radial retaining pins as each segment is installed. Where plugs are used to hold the re-

taining pins, install the access plug so that it just bottoms on the retaining pin. Tighten the access

plugs against the retaining pins and stake each plug at four places on the edge of the threads.

8. Where pins are secured in place by holding plates, lockplates are to be used to lock the hexhead

bolts.

Operation 6 — How to Recheck First Stage Nozzle Concentricity

Note:

Assistance from your General Electric Company Apparatus and Engi-

neering Service Operation Field Service Representative is recom-

mended when making concentricity checks.

1. Take the concentricity readings as shown on Inspection Form PGS/GT-FF-6097. Record all read-

ings on the inspection form. Report readings to your General Electric Company Field Service

Representative for evaluation and disposition.

Note:

The first-stage nozzle is to be concentric with the support ring forward

outside diameter within a tolerance of 0.050 in., taking into account any

ellipticity in the first-stage nozzle assembly. Refer to the Alignment

Diagram in the Reference Drawing section of this Service Manual.

The first-stage nozzle alignment should not be changed without first

consulting your General Electric Company Field Service Representa-

tive.

Operation 7 — How to Recheck Turbine Clearances

1. All turbine clearances should be retaken per hot gas path inspection disassembly operation num-

ber eight (8) in this section and checked by your General Electric Company Field Service Repre-

sentative prior to reassembly of the turbine casing upper half.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...