Combustion Inspection — Inspection Procedures

Inspection and Maintenance — GEK 107048

CI-I-23

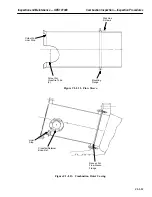

Note:

Repair welding procedures will not be described except to note that

GTAW (Gas Tungsten Arc Welding) is the only weld repair procedure

allowed on MS-6001B transition pieces. It is generally recommended

that transition pieces requiring repairs be sent to a qualified General

Electric Company Gas Turbine repair facility.

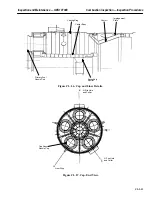

Operation 9 — How to Inspect Combustion Flow Sleeves

1. Using a bright light and ten (10) power magnifying glass, inspect the combustion casing flow

sleeves.

2. Use Figures CI-I.12 and CI-I.13 for identification of parts and Table CI-5 for inspection limits.

Record all findings on Inspection Form PGS/GT-FF-6409.

a. Inspect the sleeve for body or weld cracks, out-of-roundness, burn-through, missing metal and

wear.

b. Inspect flange to body weld for cracks or cracks in the flange.

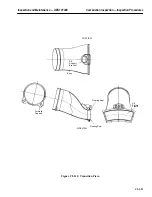

Operation 10 — How to Inspect Combustion Casings

1. Inspect inside and outside of combustion casings for cracks, bulging, buckling signs of overheat-

ing and corrosion.

2. Inspect casings 3, 4, 5, 6 and 7 false start drain holes for plugging or blockage.

3. Inspect liner stops for wear. If there is more than 0.03 inch wear on the liner stop contact surfaces,

the liner stop must be replaced or repaired.

4. Inspect all thread inserts in the crossfire, spark plug, and flame detector flanges. Replace inserts

if necessary.

5. Report condition and findings on Inspection Form PGS/GT-FF-6403.

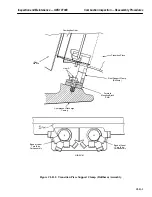

Operation 11 — How to Inspect the First Stage Nozzle

1. Use a borescope through the inspection ports, if applicable. Inspect the first stage nozzle for corro-

sion, erosion cracks, deposits and foreign object damage. See Section 4, Scheduled Turbine Main-

tenance, “Special Inspections,” of this Service Manual.

2. If borescope inspection cannot be performed make a visual inspection of the first stage nozzle.

3. Report condition and findings on inspection report forms PGS/GT-FF-6095 and 6096.

Operation 12 — How to Inspect and Test the Spark Plugs

1. Inspect the spark plug assembly for wear between the tip and the hole in the liner or overheating

damage to the tip.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...