Inspection and Maintenance — GEK 107048

Hot Gas Path Inspection — Inspection Procedures

HGP-I-12

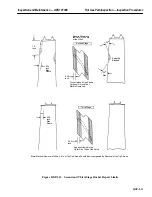

a. Second stage bucket cracks are repairable if located in the outer 20% of the airfoil and up to

0.250 in. in length. See Figure HGP-I.12 Second Stage Bucket Repair Limits.

b. Third Stage bucket cracks are repairable if located in the outer (1/3) one-third of the airfoil

and up to 0.350 in. in length. See Figure HGP-I.12 Third Stage Bucket Repair Limits.

These cracks can be repaired by blending the airfoil in the area of the crack while maintaining

radii at all intersection points. The leading edge radius must also be retained in the repaired

area.

2. Missing Metal — Missing material in the second and third stage buckets is acceptable if the airfoil

can be contoured to the same limits as crack repair.

3. Dents — Dents are acceptable, as long as the dent is not located in the bucket root fillet (interface

between airfoil and platform) or in the shroud fillet (interface between airfoil and shroud).

Dents containing cracks or those located in the shroud fillet are repairable. Repairable dents should

be hand polished to remove foreign material in the area of the dent, and fluorescent penetrant in-

spected for cracks. Blend smooth all dents.

4. Air-cooled second stage buckets must pass a 0.050 in. diameter wire through all four holes from

the bucket tip to beyond the platform. An additional check should be made to insure that the pas-

sageway through the bucket shank is open and clear.

5. Corrosion — Corrosion on second and third stage buckets to a depth of more than 0.025 in. has

not been observed. Such a condition is acceptable. If a more serious corrosion is noted, the obser-

vations should be reported to your General Electric Company Field Service Representative.

Radial Seal Pin Grooves

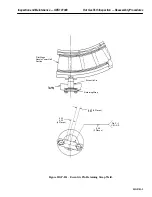

Radial Seal Pin Groove Repair Limits, see Figure HGP-I.13.

Cracks and damaged material may be blended within these allowances:

1. Region I — No missing material allowed

2. Region II — Outer lands 0.500 in. missing metal on both sides

3. Region III — No missing material allowed

4. Region IV — Blending allowed in this region

Wheelspace Seals/Angel Wings

Rubbed wheelspace seals are suitable for continued operation as long as the corresponding wheel-

space temperatures are within operating limits.

Axial cracks are common and are acceptable in region “A” providing they do not penetrate the seal

to shank radius “B” shown in Figure HGP-I.14.

Seals that have the upturned edge rubbed off are unsuitable for use, see Figure HGP-I.14.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...