Inspection and Maintenance — GEK 107048

Hot Gas Path Inspection — Reassembly Procedures

HGP-R-18

8. Install 11th stage cooling and sealing air lines.

Note:

Install all the 11th stage cooling and sealing air piping except the upper

right side section with the compressor bleed valve (33CB-2). This sec-

tion will be installed after the exhaust plenum access upper panel is re-

installed.

9. Install primary, secondary and transfer gas fuel lines.

10. Install turbine casing blank cover on hand holes port or the air extraction manifold.

11. Install secondary flame detectors.

12. Reconnect the ignitors.

Operation 14 — How to Reassemble Exhaust and Inlet Duct Access Panels

1. On a straight up exhaust configuration spread the exhaust plenum frame using a length of 4 in.

pipe or timber and a 10 ton mechanical jack sufficiently to allow clearance to install the access

panel.

2. Assemble new gasket, lift and position the panel into the plenum opening. Coat bolting with Fel

Pro C-102 anti-seize compound, install bolts but do not tighten.

3. Assemble new gasket to the exhaust duct transition piece forward panel. Lift and guide the panel

into position.

Note:

Comealongs will be required to help guide and position the panel into

location underneath the overhang of the duct transition piece.

4. Coat bolts with Fel Pro C-102 anti-seize compound. Install bolts and tighten. Remove the rigging.

5. Tighten the bolts on the exhaust plenum panel.

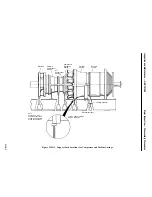

6. Reassemble the exhaust plenum forward flex seals gaskets and clamp bars between the exhaust

hood frame and plenum. See Figure HGP-R.8.

7. Reinstall the 11th stage extraction piping and compressor bleed valve to the exhaust plenum pan-

el. Reconnect all tubing runs and piping runs to the 11th stage piping and bleed valve.

8. Inspect the inlet plenum for cleanliness and or foreign objects. Install new gasket on the inlet ple-

num access panel located in the lower right hand section of the plenum, looking with air flow.

Coat bolts with anti-seize compound, install access panel and bolt in place.

Operation 15 — How to Assemble Turbine Compartment Roof, Side Panels and Doors

1. Reassemble lagging side panel vertical beams if they were removed at disassembly.

2. Attach four eyebolts to threaded receptacles on the roof. Rig the roof (include chainfall in rigging)

for lifting.

3. Apply new gasketing or caulking to roof section.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...