Inspection and Maintenance — GEK 107048

Major Inspection — Disassembly Procedures

MI-D-4

7. Remove secondary fuel gas lines.

8. Remove false start drain tubing and manifold header.

9. Remove secondary fuel nozzles.

10. Remove the spark plugs.

11. Remove 11th stage cooling and sealing air lines.

Note:

The 5th stage cooling and sealing air lines and the bearing sealing air

valve (VA14), if used, must also be removed from the upper half com-

pressor casing at this time.

12. Remove fuel nozzle/end cover assemblies.

13. Remove crossfire tube retainers, combustion liners and crossfire tubes.

14. Remove access port blank flange or air extraction piping manifold from upper section of turbine

casing.

15. Remove outer combustion casings.

Operation 3 — How to Remove Exhaust and Inlet Duct Access Panels

1. On straight up exhaust configurations, unbolt the removable exhaust duct transition piece panel

on the forward side of the panel.

2. On side exhaust configurations remove any architectural lagging, support members which may

interfere with turbine casing removal. Remove the cowl section from the top of the exhaust ple-

num. This will facilitate access to the exhaust hood for removal.

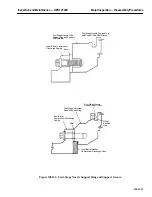

3. Remove the 11th stage extraction pipe and compressor bleed valve by unbolting the bleed valve

flange at compressor, loosen the “U” bracket, bellows clamp, and tubing connections and slip the

piping out of the slip joint.

4. Remove the forward and aft flex seal clamp bars and the flex seal plates.

5. Unbolt the forward exhaust plenum removable access panel. Rig to lift the panel.

6. Install a length of 4 in. pipe or timber and a mechanical jack across the horizontal opening of the

plenum and spread the panel sufficiently enough to remove the access panel. Lift the panel clear

of the unit.

7. Unbolt and remove the inlet plenum access door located in the lower right hand section of the ple-

num, looking with airflow.

Operation 4 — How to Take Initial Compressor and Turbine Rotor Positioning Checks

1. Refer to the Hot Gas Path Inspection, disassembly operation number 3 in this instruction manual,

for positioning checks procedure.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

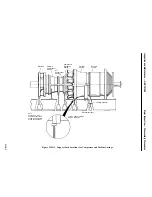

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

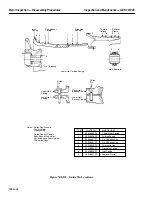

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...