Hot Gas Path Inspection — Disassembly Procedures

Inspection and Maintenance — GEK 107048

HGP-D-13

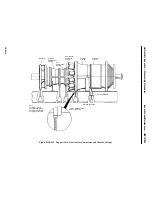

3. Prepare for and take clearances around the second stage nozzle.

a. With the rotor still in the forward position, position the second stage nozzle and diaphragm

(left and right) downstream by first wedging a screwdriver in the first stage shroud to second

stage nozzle outer sidewall gap. Assure that the second stage nozzle aft outer sidewall hooks

are seated downstream in the second stage shrouds, and that the second stage shrouds are

seated downstream against the turbine shell. See Figure HGP-D.5.

Second, drive a wooden wedge between the forward face of the nozzle diaphragm and the first

stage bucket shanks. Drive the wooden wedge until the diaphragm forward male hook is

seated downstream against the nozzle female hook. At this point, the wooden wedge should

be firmly in place. The downstream seated condition is indicated on Figure HGP-D.5 with

notation “These gaps must be closed.”

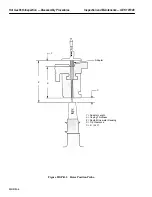

The wooden wedge can be cut from a 2 x 4 and when possible, be made from structural grade

of wood. Dimensions of the wedge are shown in Figure HGP-D7.

Note:

Do not wedge third stage nozzle and diaphragms until all second stage

nozzle area clearances have been taken.

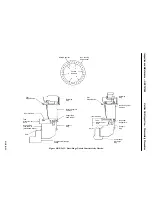

b. Measure the “A” set point and “A” set point complements. See Figure HGP-D.8.

Measure the “A” set point, “A,” between the forward flat side, not the pointed portion, of the

first diaphragm seal tooth and the aft side of the first land of the 1–2 spacer.

Measure the “A” set point complements, “A

C

,” between the aft flat side, not the pointed posi-

tion of each diaphragm seal tooth and the forward side of each spacer land. Proceed with the

forward tooth first for “A

C1

” and proceed downstream for “A

C2

,” “A

C3

,” etc. Record data on

Inspection Form PGS/GT-FF-6105.

c. Measure all radial and axial clearances around the second stage nozzle. Record on Inspection

Form PGS/GT-FF-6105.

Note:

1. Do not wedge the third stage nozzles simultaneously with the second

stage nozzles.

2. Do not measure the “A” set point or complements with a snap gauge.

It is recommended to use a parallel bar and feeler stock. See Figure

HGP-D.9.

3. The wooden wedge is used only to maintain proper downstream

seating of the diaphragm while taking clearances. Do not drive the

wedge hard. The wedge should produce inappreciable nozzle elastic

deformation. If the wooden wedge has to be driven hard to “shock”

the diaphragm downstream, take the wedge out and drive another

wedge just until it becomes firmly in place before taking clearances.

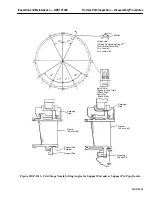

4. Prepare for and take clearances around the third stage nozzle.

a. With the rotor remaining in the forward position, position the third stage nozzles and dia-

phragm downstream similar to the second stage nozzles and diaphragms. See Figure

HGP-D.6.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...