Inspection and Maintenance — GEK 107048

Combustion Inspection — Reassembly Procedures

CI-R-4

Note:

Torquing procedure; to minimize variations in clamping force of bolt

for given torque values, bolts must be torqued backed off, then

retorqued.

4. Torque the support clamp (bullhorn) bolts to 33–37 lb. ft. then loosen and remove bolts and lock-

plates from the support clamp.

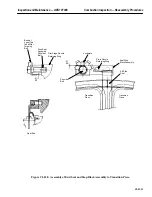

5. Slide number four (4) transition piece over the positioning pin to support the transition piece. In-

sert the floating seals into their respective slots in the first stage nozzle. Assemble the support

clamp to the transition piece forward mounting bracket slots. Install the support clamp lockplates,

and bolts. Bolt the support clamp to the compressor discharge casing. Do not tighten bolts or bend

lockplates at this time.

6. Install the aft bracket bolts and lockplates and tighten to the first stage nozzle retaining ring. Prior

to torquing the bolts, check for proper floating seal engagement to the first stage nozzle segment

slots. Torquing aft bracket bolts with floating seals out of their slots will result in damage to seal.

Torque aft bracket bolts to 75–85 lb. ft. Do not bend lockplate tabs at this time.

7. Torque the support clamp bolts to 33–37 lb. ft. then loosen and remove bolts and lockplates from

the support clamp.

8. Repeat steps 5, 6 and 7 for number six (6) transition piece.

9. Starting with number five (5) transition piece, check the spacing between four and five, five and

six transition pieces at the transition piece side seal slot. The spacing should be between

0.36–0.53 in. To align the number five (5) transition piece the aft bracket bolts on number four

(4), five (5) and six (6) transition pieces may have to be loosened. After alignment is achieved

on number five (5) transition piece, retorque the aft bracket bolts to 75–85 lb. ft. See Figure

CI-R.3.

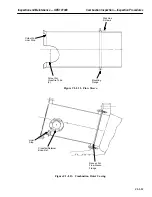

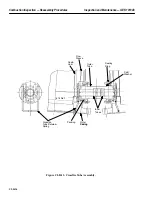

10. Measure the radial and circumferential displacement of the transition piece with respect to the

compressor discharge casing. Using a carpenters square or two scales (rulers), measure the con-

centricity of the transition piece to the compressor discharge casing at four (4) points (radial out-

side position and every 90

°

from that point). If displacement does not exceed 0.100 in. radially

or circumferentially, proceed to step 11. See Figure CI-R.4.

CAUTION

If measured displacement exceeds 0.100 in. further as-

sembly should not be attempted. Contact your General

Electric Company Field Service Representative for cor-

rective action.

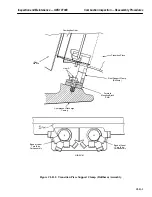

11. The support clamp bolts may be torqued after the #5 transition piece has been aligned per step

10 above, and correct contact at the support clamp has been achieved (see Figure CI-R.5.). The

support clamp contact must be maintained after the bolts are torqued.

Note:

Nominal shim thickness for the support clamp is 0.0 in. A maximum of

three (3) shims for a thickness of 0.100 in. may be used if required to

achieve proper loading of the support clamp.

Содержание MS6001B

Страница 2: ...Gas Turbine Inspection and Maintenance GEK 107048 I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...Inspection and Maintenance Note THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...Inspection and Maintenance Notes Cautions and Warnings viii THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 13: ...INSERT TAB INTRODUCTION ...

Страница 14: ......

Страница 25: ...INSERT TAB STANDARD PRACTICES ...

Страница 26: ......

Страница 57: ...Standard Practices Inspection and Maintenance GEK 107048 SP 31 Figure 2 26 Rail Fabrication Hoist ...

Страница 58: ...Inspection and Maintenance GEK 107048 Standard Practices SP 32 Figure 2 27 Pulley Nozzle Segments ...

Страница 59: ...Standard Practices Inspection and Maintenance GEK 107048 SP 33 Figure 2 28 Typical Borescope Kit ...

Страница 60: ...Inspection and Maintenance GEK 107048 Standard Practices SP 34 Figure 2 29 Rail Channel Trolley ...

Страница 61: ...Standard Practices Inspection and Maintenance GEK 107048 SP 35 Figure 2 30 Lifting Beam Inlet Silencer ...

Страница 62: ...Inspection and Maintenance GEK 107048 Standard Practices SP 36 Figure 2 31 Lifting Beam Inlet Transition ...

Страница 63: ...Standard Practices Inspection and Maintenance GEK 107048 SP 37 Figure 2 32 Lifting Beam Inlet Elbow ...

Страница 66: ...Inspection and Maintenance GEK 107048 Standard Practices SP 40 Figure 2 38 Tubing Insert and Male Connector ...

Страница 86: ...Inspection and Maintenance GEK 107048 Standard Practices SP 60 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 87: ...INSERT TAB AUXILIARY CONTROLS SYSTEMS MAINTENANCE ...

Страница 88: ......

Страница 90: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...Auxiliary and Controls Systems Maintenance Inspection and Maintenance ACSM 14 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...Inspection and Maintenance Procedures Inspection and Maintenance I 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 132: ...Inspection and Maintenance Procedures Inspection and Maintenance IMP 26 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...INSERT TAB SCHEDULED TURBINE MAINTENACE ...

Страница 134: ......

Страница 153: ...Scheduled Turbine Maintenance Inspection and Maintenance GEK 107048 STM 19 Figure 4 2 Borescope Light Supply ...

Страница 156: ...Inspection and Maintenance GEK 107048 Scheduled Turbine Maintenance STM 22 Figure 4 5 TV Monitor Presentation ...

Страница 157: ...INSERT TAB COMBUSTION INSPECTION ...

Страница 158: ......

Страница 160: ...Inspection and Maintenance GEK 107048 Combustion Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 239: ...INSERT TAB HOT GAS PATH INSPECTION ...

Страница 240: ......

Страница 242: ...Inspection and Maintenance GEK 107048 Hot Gas Path Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 313: ...INSERT TAB MAJOR INSPECTION ...

Страница 314: ......

Страница 316: ...Inspection and Maintenance GEK 107048 Major Inspection 2 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 350: ...Inspection and Maintenance GEK 107048 Major Inspection Inspection Procedures MI I 8 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 363: ...INSERT TAB MAINTENANCE FORMS ...

Страница 364: ......

Страница 370: ...Inspection and Maintenance GEK 107048 Maintenance Forms MF 6 THIS PAGE INTENTIONALLY LEFT BLANK ...